---------------------------------------------- Product Description:

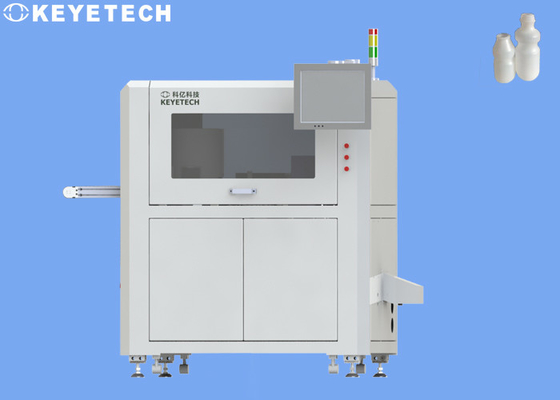

The Bottle Inspection System is designed for inspecting the quality of a wide range of bottles, providing accurate and effective evaluation of a variety of bottle attributes. The system consists of a main control board and a variety of inspection items, such as caps, labels, bottle body and more. This system is capable of detecting and detecting defects in the inspected items, ensuring the quality of the bottles. The system has an average power consumption of 5kw-7kw and operates with an AC220V/50Hz power supply. Its dimension is 3000x1200x1800mm.

The Bottle Inspection System is a reliable and efficient bottle quality checker that ensures the highest quality of bottles. It quickly and accurately inspects bottle caps, labels, and body for any defects or inconsistencies, offering a comprehensive evaluation of the bottle's overall quality. The system also comes with a variety of settings that can be adjusted to meet specific inspection needs, making it a reliable and versatile quality control solution.

The Bottle Inspection System is an essential tool for ensuring the quality of bottles. It offers an efficient and accurate way to evaluate and inspect a variety of bottle attributes, offering a reliable and effective solution for quality control. The system is easy to set up and operate, making it a great choice for a wide range of bottle inspection needs.

Features:

- Bottle Quality Checker: Bottle Inspection System

- Optical: OEM BY KEYE

- Weight: 300-500Kg

- Inspection Speed: 60-100 Bottles/min

- Rejection Rate: ≤0.5%

- Display: Touch Screen

- Bottle Analysis System: Bottle Inspection System

- Bottle Quality Checker System: Bottle Inspection System

Applications:

KEYE KVIS-B Bottle Inspection System

KEYE KVIS-B Bottle Inspection System is an advanced machine for bottle analysis and measurement. It is certified by CE/ISO/UL, and the minimum order quantity is 1 SET. The price is negotiable and the packaging is plywood carton. The delivery time is 6-8 weeks and payment terms are TT, L/C, Paypal, or Credit Card. The supply ability is 30 sets per month, and the power supply is AC220V/50Hz. The dimension is 3000x1200x1800mm and the rejection method is air blowing. The camera is 300 Megapixels (KEYE) and the inspection item covers cap, label, bottle body, etc.

KEYE KVIS-B Bottle Inspection System is a perfect solution for bottle quality checker, bottle checking machine, bottle detection system. It is highly accurate and easy to use. With this machine, you can accurately and efficiently inspect bottles for any defects. It also provides comprehensive data analysis and reporting. The system can detect any minor defects and ensure the finished products meet the highest quality standards.

Customization:

Do you need a reliable Bottle Inspection System? KEYE’s Bottle Analysis System, model KVIS-B, is the perfect choice. Our Bottle Quality Checker is certified by CE/ISO/UL and has a minimum order quantity of 1 SET. The price is negotiable and it comes with a Plywood Carton. The delivery time is 6-8 weeks and you can pay using TT, L/C, Paypal, or Credit Card. We have a supply ability of 30 Sets Per Month with a rejection rate ≤0.5%. It has an HMI interface for easy operation and an inspection accuracy of 99.5%. Get the Bottle Analysis System and benefit from its fast inspection speed of 60-100 Bottles/min.

Support and Services:

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time.

And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

Packing and Shipping:

Packaging and Shipping for Bottle Inspection System:

The Bottle Inspection System is packaged in sturdy, corrugated carton boxes that are designed to protect the system during shipping. Each box is labeled with a unique serial number, identifying the contents of the package and the destination address. The boxes are then sealed with strong adhesive tape and are shipped with a reliable freight forwarder.

FAQ:

- Q1: What is the brand name of the Bottle Inspection System?

- A1: The brand name of the Bottle Inspection System is KEYE.

- Q2: What is the model number of the Bottle Inspection System?

- A2: The model number of the Bottle Inspection System is KVIS-B.

- Q3: What is the place of origin of the Bottle Inspection System?

- A3: The place of origin of the Bottle Inspection System is China.

- Q4: What is the minimum order quantity of the Bottle Inspection System?

- A4: The minimum order quantity of the Bottle Inspection System is 1 SET.

- Q5: What are the payment terms for the Bottle Inspection System?

- A5: The payment terms for the Bottle Inspection System are TT, L/C, Paypal, and Credit Card.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!