Product Description:

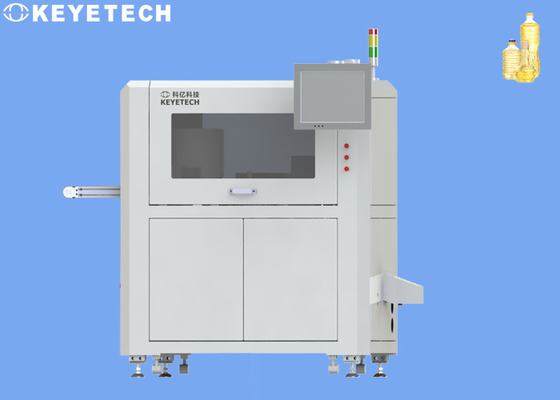

Bottle Inspection System is a comprehensive bottle measurement system that can accurately verify the quality of bottles. It is equipped with OEM BY KEYE optical sensors, and can identify defects in bottles with an ultra-low rejection rate of ≤0.5%, effectively ensuring product quality. Its power consumption is only 5kw-7kw, and its dimension is 3000x1200x1800mm. The system utilizes an advanced air blowing rejection method to reject the bottles that do not meet the standards. This Bottle Quality Checker is the perfect solution for quality control in the bottle manufacturing industry.

Features:

| 1.Product Name: Bottle Inspection System |

| 2.Power Consumption: 5kw-7kw |

| 3.Optical: OEM BY KEYE |

| 4.Dimension: 3000x1200x1800mm |

| 5.Rejection Rate: ≤0.5% |

| 6.HMI: Support |

| 7.Bottle Measurement System: Yes |

| 8.Bottle Verification System: Yes |

| 9.Bottle Quality Checker: Yes |

Applications:

KEYE KVIS-B Bottle Inspection System is a reliable and efficient automatic system used for bottle quality evaluation and verification. It is certified to meet CE/ISO/UL standards and is required to have a minimum order quantity of one set. The power consumption for this system is between 5kw-7kw and it is powered by AC220V/50Hz. The rejection rate is ≤0.5%, and the rejection method is through air blowing. The price of the KEYE KVIS-B Bottle Inspection System is negotiable and the delivery time is 6-8 weeks. Payment terms include TT, L/C, Paypal, Credit Card. The packaging is in a plywood carton and the supply ability is up to 30 sets per month.

The KEYE KVIS-B Bottle Inspection System is suitable for a wide variety of bottle inspection applications including beverage, pharmaceutical, food, chemical, and cosmetic inspection. The system is capable of verifying the shape, size, weight, color, code, label, and cap of the bottles and can also detect impurities and defects. With its high precision and accuracy, the KEYE KVIS-B Bottle Inspection System can detect and reject defective bottles at a very low rate of ≤0.5%.

The KEYE KVIS-B Bottle Inspection System is an ideal choice for companies looking for an efficient and reliable bottle inspection system. It is capable of accurately detecting and rejecting defective bottles, while providing accurate and precise results. With its low power consumption, high rejection rate, and easy to use interface, the KEYE KVIS-B Bottle Inspection System is the perfect choice for any business looking to improve their bottle inspection process.

Customization:

Bottle Inspection System

KEYE's Bottle Inspection System is designed to detect defects in bottles, caps, labels and other areas. It is equipped with a high-precision optical system, touch screen display and other advanced components, providing accurate and reliable detection results. It is suitable for automatic production line inspection and quality control.

- Brand Name: KEYE

- Model Number: KVIS-B

- Place of Origin: CN

- Certification: CE/ISO/UL

- Minimum Order Quantity: 1 SET

- Price: Negotiable

- Packaging Details: Plywood Carton

- Delivery Time: 6-8 weeks

- Payment Terms: TT, L/C, Paypal, Credit Card

- Supply Ability: 30 Sets Per Month

- Inspection Item: Cap, Label, Bottle Body, Etc.

- Display: Touch Screen

- Dimension: 3000x1200x1800mm

- Optical: OEM BY KEYE

- Type: Automatic

KEYE's Bottle Inspection System is an ideal solution for bottle quality checker and bottle measurement system. Through the inspection of bottles, labels and other areas, it can help to ensure the quality of the products and reduce the defective rate.

Support and Services:

Bottle Inspection System Technical Support and Service

We provide technical support and service for our Bottle Inspection System. Our support team is available 24/7 to help you with any issue you may have.

We offer a range of services, including:

- Installation and configuration

- Troubleshooting and repair

- Maintenance and upgrades

- Data analysis and reporting

- System optimization

We also provide online resources, such as user guides, tutorials, and FAQs, to help you get the most out of your Bottle Inspection System.

Packing and Shipping:

Packaging and Shipping for Bottle Inspection System

The Bottle Inspection System is packaged and shipped in accordance with the following procedures:

- The product is placed in a cardboard box and sealed with packing tape.

- The box is then placed in a shipping container with packing materials.

- The shipping container is sealed with a tamper-evident seal.

- The shipping container is then labeled with the appropriate shipping information.

- The shipping container is then loaded onto a pallet for transport.

FAQ:

- Q1: What is the Brand Name of the Bottle Inspection System?

- A1: The Bottle Inspection System is made by KEYE.

- Q2: What is the Model Number of the Bottle Inspection System?

- A2: The Model Number for the Bottle Inspection System is KVIS-B.

- Q3: Where is the Bottle Inspection System manufactured?

- A3: The Bottle Inspection System is manufactured in China.

- Q4: What certifications does the Bottle Inspection System have?

- A4: The Bottle Inspection System is certified by CE/ISO/UL.

- Q5: What is the minimum order quantity for the Bottle Inspection System?

- A5: The minimum order quantity for the Bottle Inspection System is 1 SET.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!