Product Description:

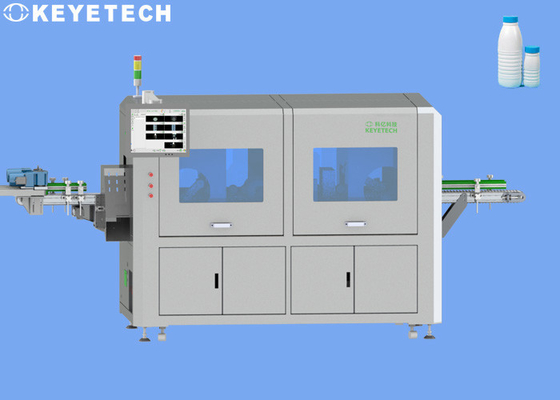

Bottle Inspection System is a high-speed, low-power and compact automated system designed to inspect bottles and ensure high-quality production. It can evaluate up to 60-100 bottles per minute and consume 5kw-7kw of power. It has a dimension of 3000x1200x1800mm and is equipped with an OEM custom-made optical system by Keye for accurate inspection and measurement of bottle caps, labels, and bottle bodies. It is an ideal solution for bottle quality evaluation and verification, providing reliable and accurate results.

This Bottle Evaluation System is ideal for quality control and assurance of any production line. It is a reliable and accurate Bottle Measurement System that is capable of detecting defects in bottles such as broken caps, incorrect labels, and damaged bottle bodies. It is also capable of providing real-time feedback and analysis of the bottle quality inspection process. This Bottle Verification System is a cost-effective solution for any production line, ensuring the highest-quality production of bottles.

The Bottle Quality Inspection System provides a fast and reliable way to ensure high-quality production. With its robust and adjustable design, it can be tailored according to specific requirements, providing maximum accuracy and efficiency. This system is a reliable and easy-to-use tool for any production line, helping to improve the quality of bottles produced and reduce waste.

Features:

| 1.AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training |

| 2.Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3.Multi-orientation: 360 degree comprehensive inside and outside the samples |

| 4.High precision: detection accuracy can be high |

| 5.Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6.Easy to operate: It is easy to operate and easy to maintain |

| 7.Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

Applications:

KEYE KVIS-B Bottle Inspection System

KEYE Bottle Inspection System is an advanced automatic bottle quality checker, bottle evaluation system, and bottle measurement system certified by CE/ISO/UL. Made of stainless steel and equipped with AI algorithm, it features fast detection speed of 60-100 bottles/min. One set of KEYE KVIS-B Bottle Inspection System is available for purchase with minimum order quantity of 1 set. The price is negotiable and the delivery time is 6-8 weeks.

The packaging of KEYE KVIS-B Bottle Inspection System is plywood carton and payment terms include TT, L/C, Paypal, and Credit Card. The Supply Ability of KEYE KVIS-B Bottle Inspection System is 30 sets per month. KEYE KVIS-B Bottle Inspection System is designed for ensuring the accuracy and consistency of bottle quality for various industries.

Customization:

Custom Bottle Inspection System

Brand Name: KEYE

Model Number: KVIS-B

Place of Origin: CN

Certification: CE/ISO/UL

Minimum Order Quantity: 1 SET

Price: Negotiable

Packaging Details: Plywood Carton

Delivery Time: 6-8 weeks

Payment Terms: TT, L/C, Paypal, Credit Card

Supply Ability: 30 Sets Per Month

Product Name: Bottle Inspection System

Core Technology: AI Algorithm

HMI: Support

Inspection Item: Cap, Label, Bottle Body, Etc.

Power Supply: AC220V/50Hz

KEYE's Bottle Inspection System is designed to help you complete fast, accurate and reliable bottle analysis. Adopting the advanced AI Algorithm, our bottle analysis system can inspect cap, label, bottle body, etc. With HMI support, it can be easily operated by users. The power supply is AC220V/50Hz. All the products are certified with CE/ISO/UL. The minimum order quantity is 1 SET, and the price is negotiable. The packaging details is plywood carton, and the delivery time is 6-8 weeks. We accept payment terms of TT, L/C, Paypal, Credit Card. The supply ability is up to 30 sets per month.

Support and Services:

Bottle Inspection System Technical Support and Service

The Bottle Inspection System provides 24/7 technical support and service. This includes:

- On-site installation and maintenance

- Remote troubleshooting and repair

- Software and hardware upgrades

- Data backup and recovery

- Replacement parts and accessories

We also offer training and consulting services, including:

- Operator training

- System integration and customization

- Technical support and service plans

For more information about our technical support and service, please contact us.

Packing and Shipping:

Packaging and Shipping for Bottle Inspection System

The Bottle Inspection System is securely packaged for shipping. All components are carefully secured in a durable corrugated cardboard box with the appropriate amount of foam padding to ensure that they are not damaged during transit.

The package also includes detailed instructions on how to assemble and use the Bottle Inspection System. It also includes a list of safety precautions and warnings that must be observed during the installation and operation of the system.

The package is clearly labeled with the product name, model number, and other important information. The package is also clearly marked "FRAGILE" to ensure that it is handled with care during transit.

The Bottle Inspection System is shipped via a reliable, insured carrier to ensure that it arrives safely and on time.

FAQ:

- Q: What is the brand name of Bottle Inspection System?

- A: The brand name of Bottle Inspection System is KEYE.

- Q: What is the model number of Bottle Inspection System?

- A: The model number of Bottle Inspection System is KVIS-B.

- Q: Where is the place of origin of Bottle Inspection System?

- A: The place of origin of Bottle Inspection System is China.

- Q: What certifications are available for Bottle Inspection System?

- A: The certifications available for Bottle Inspection System are CE/ISO/UL.

- Q: What is the minimum order quantity for Bottle Inspection System?

- A: The minimum order quantity for Bottle Inspection System is 1 SET.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!