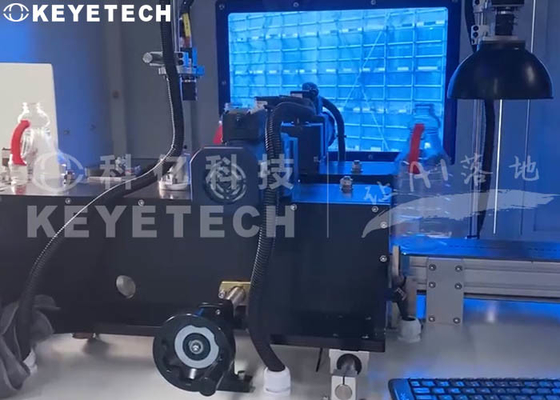

PET Bottle Quality Inspection Equipment Inline Camera Detection System

Features of system

|

1. Start the inspection equipment and open the inspection software

|

|

2. The inspection system is in standby

|

|

3. When the product reaches the position where the visual inspection camera takes pictures, the camera starts to take pictures.

|

|

4. The inspection system judges OK/NG and sends a signal to the rejection device

|

|

5. The rejection device is in standby

|

|

6. If it is NG, it will automatically stop or reject (discharge) processing

|

|

7. If it is OK, do not process

|

Inspection principle

With people's attention to food safety issues, more and more manufacturers introduce machine vision technology into actual production to achieve the purpose of improving production efficiency and product quality. In order to ensure the quality of each bottle of soy sauce to the greatest extent, soy sauce manufacturers will conduct various tests to check the quality before the products leave the factory.

Manual inspection is prone to false detection and low efficiency, and has been gradually replaced by visual inspection equipment. The production date coding on the soy sauce bottle is one of the important indicators for consumers to judge food safety. Therefore, before the soy sauce leaves the factory, the OCR, liquid level and bottle cap of the soy sauce bottle need to be tested.

Inspection details

- Install an OCR character visual detection system on the soy sauce production line;

- When the soy sauce bottle flows into the visual inspection station, the image of the bottle taken by the machine vision sensor is triggered and sent to the system. The system extracts and analyzes the captured image and compares it with the set one to know whether the cap of the soy sauce bottle is tightened properly and whether the liquid level is in place. Within the standard working tolerance range, whether the inkjet code is correct;

- When it is detected that the cap of the soy sauce bottle is not tightened in place, the liquid level is not within the standard tolerance range, or the coding is wrong, the system sends a signal to the rejecting device for rejecting processing and alarm prompts.

In each production stage, it is equipped with machine vision to identify these characters, barcodes or QR codes, and associates these information in the background to achieve the traceability of the production process.

Company profile

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

** Our company have served many well-known enterprises such as Coca-Cola, P&G,Unilever,ALPLA,C'estbon, Nongfu Spring, etc., and has won praise from many users.

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!