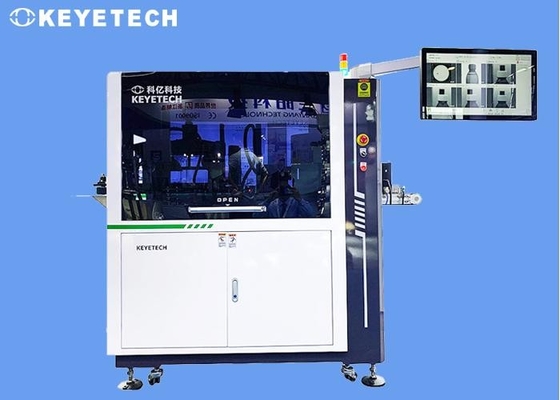

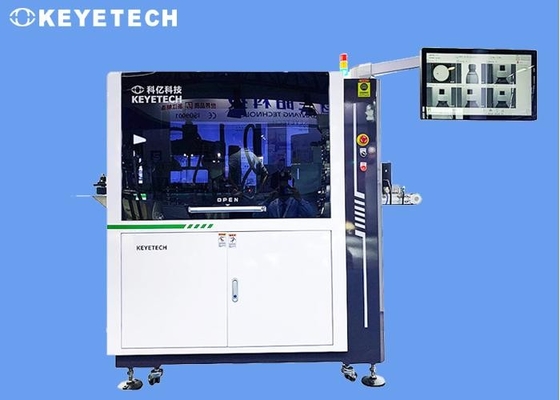

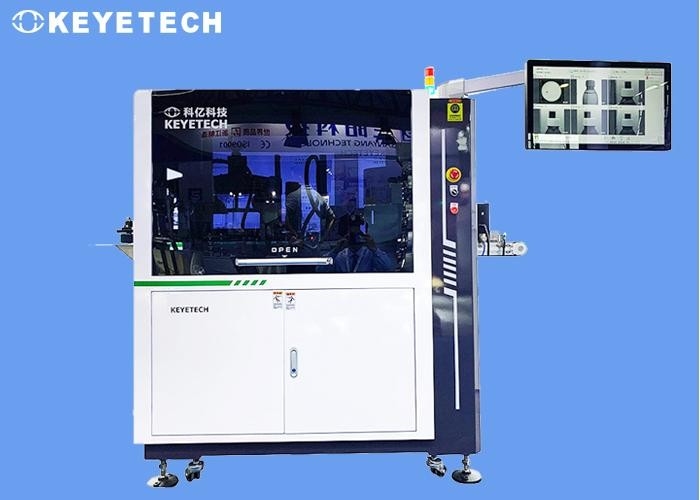

Penicillin Bottle Inspection System For Surface Label & Defective Checking

Equipment features

|

1. AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training

|

| 2. Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3. Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4. High precision: detection accuracy can be high |

| 5. Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6. Easy to operate: It is easy to operate and easy to maintain |

| 7. Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

Inspection principle

The application of glass bottles for medicine or beverages has become very common. With the increasingly fierce competition, customers are bound to have higher and higher requirements for the quality of glass bottles, which has higher and higher requirements for the product quality of glass bottle companies. In order to fully resolve this increasingly acute contradiction, it is usually adopted to continuously increase the intensity of manual monitoring, or to find better detection methods.

In order to improve the quality of products leaving the factory, manufacturers usually rely on a large number of manual inspections to pick out waste products. However, manual inspection is slow and requires a lot of manpower, material resources, and site resources. Moreover, after working for a long time, the human eye is prone to fatigue and negligence, and cannot efficiently guarantee product quality.

Inspection details

The machine vision inspection system refers to converting the ingested target into an image signal through machine vision products (CMOS and CCD), sending it to a dedicated image processing system, and converting it into a digital signal according to information such as pixel distribution and brightness. The image system performs various calculations on these signals to extract the characteristics of the target, and then controls the on-site equipment actions based on the discrimination results, and performs visual inspection, dimension measurement, defect detection, and system positioning.

- Install glass bottle mouth defect detection system on the production line;

- When the glass bottle flows into the visual inspection station, the picture of the bottle mouth of the glass bottle is sent to the system by triggering the machine vision sensor, and the system extracts and analyzes the picture taken and compares it with the set one to know whether the bottle mouth is defective;

- When the glass bottle mouth is detected to be defective, the system will send out an audible and visual alarm and a shutdown signal.

The KEYE TECH glass bottle defect detection solution uses AI vision cameras to collect and identify image data of glass bottles, analyze and process the data, and then identify cracks, scratches, gaps, dirt and the thickness of glass bottles. The program finally realized the automatic inspection of glass bottle production quality.

Company profile

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!