Top Seal, Body, Injection Gate Inspection and Sorting Machines for PET Preforms

Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

Features of system

|

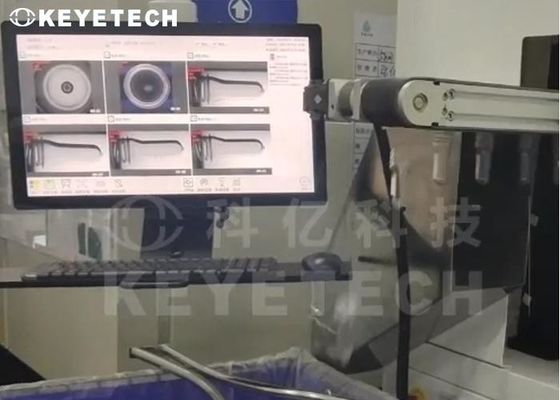

1. AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training

|

| 2. Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3. Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4. High precision: detection accuracy can be high |

| 5. Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6. Easy to operate: It is easy to operate and easy to maintain |

|

7. Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment

|

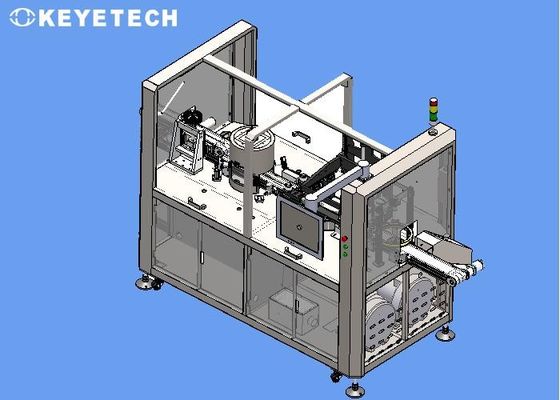

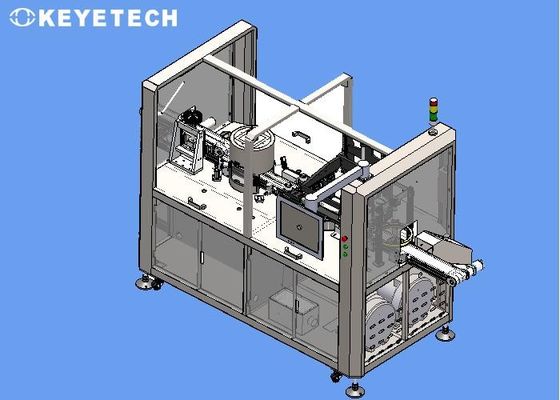

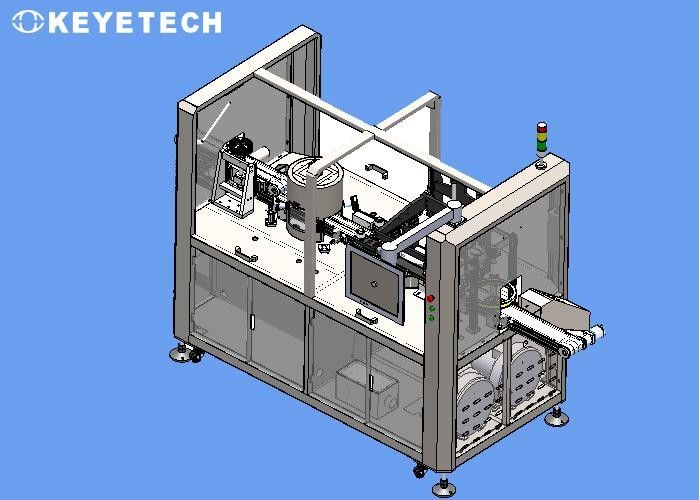

Inspection principle

The design scheme uses high-pixel industrial cameras and high-performance strobe light sources to conduct all-round visual inspection for the appearance defects of bottle products. The inspection speed is 300-400 pcs/min, and the equipment can operate 24 hours a day. Products can be automatically rejected online.

The whole set of testing equipment includes mechanical parts, visual electronic hardware and testing system software. The entrance and exit of the testing machine can be integrated with the customer's on-site conveyor line, and can be connected with upstream and downstream production equipment according to the specific production needs of the customer's site.

Technical List

| Model |

Cameras |

Detection Range |

Detection Content |

Detection Accuracy |

Accuracy Rate |

False Detection Rate |

Detection Speed |

| KY-PP |

4Set |

Around The Bottle Preform |

Black Spots, Bubbles, Impurities (Different Colors) |

≥0.3Mm |

99% |

≤0.2% |

300Pcs/Min |

| 1Set |

Preform Base |

Black Spot, Hole |

≥1.5Mm |

99% |

≤0.2% |

| 4Set |

Opening Of The Preform |

Black Spots, Stains, Impurities (Different Colors) |

≥0.2Mm |

99% |

≤0.2% |

| Overlap, Lack Of Material |

≥1Mm |

99% |

≤0.2% |

| 1Set |

Support Ring |

Lack Of Material |

≥1Mm |

99% |

≤0.2% |

After-sale Service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!