Injection Molding PET Preform Visual Inspection System 600 Pcs/Min

Inspection standards

| Model |

Cameras |

Detection Range |

Detection Content |

Detection Accuracy |

Accuracy Rate |

False Detection Rate |

Detection Speed |

| Kvis-Sc10 |

4Set |

Around The Bottle Preform |

Black Spots, Bubbles, Impurities (Different Colors) |

≥0.3mm |

99% |

≤0.2% |

300-600Pcs/Min |

| 1Set |

Preform Base |

Black Spot, Hole |

≥1.5mm |

99% |

≤0.2% |

| 4Set |

Opening Of The Preform |

Black Spots, Stains, Impurities (Different Colors) |

≥0.2mm |

99% |

≤0.2% |

| Overlap, Lack Of Material |

≥1mm |

99% |

≤0.2% |

| 1Set |

Support Ring |

Lack Of Material |

≥1mm |

99% |

≤0.2% |

Inspection principle

Food and medicine safety has become a hot topic in today's society, so it is very important to strictly control the hygiene in the production process and ensure the safety of food and medicine. In recent years, with the rapid development of packaging technology in food, medicine and other industries, the requirements of manufacturing enterprises for product packaging quality testing are also getting higher and higher.

PET (polyethylene terephthalate) preform is the semi-finished product of beverage packaging bottle, and there are inevitable defects in the production process. The preform currently has problems such as broken support ring, flash, hollow, lack of glue, air bubbles, broken bottle mouth, oval, impurities, etc., which directly or indirectly cause the unqualified final product and bring huge losses to the enterprise. How to reject defective bottles before canning is an important topic in PET bottle production.

Inspection details

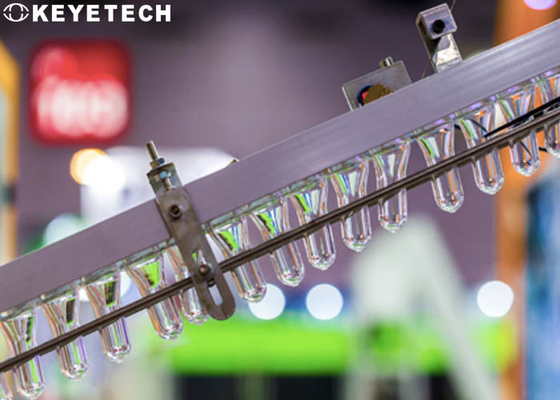

When the PET bottle preform enters the inspection machine, the photoelectric sensor triggers the signal, and the inspection system starts to track the product and prepares for image acquisition. Under the positioning of the system tracking program, it is judged that the bottle has reached the predetermined position, and the system sends out light source and image acquisition instructions. With the assistance of a specific light source, the system will capture images in real time.

After the image acquisition is completed, it will be handed over to the image processing module for identification and algorithm analysis. , judge whether the product is qualified and transmit the signal to the control system to prepare to reject the unqualified products. When the tracking program detects that the product reaches the rejection position, the control system notifies the rejection mechanism to carry out the rejection action for the defective product.

Advantages of system

This paper systematically introduces the application of visual inspection equipment in the detection of PET bottle preform defects. The system has actually been put into production. According to historical production data, the detection accuracy of the system is about 99.97%, and the missed detection rate is less than 0.1%, which can meet the online detection requirements. In practical application, the system effectively improves the production efficiency of the production line, reduces the rate of defective products in production, reduces production costs for enterprises, and greatly reduces the potential safety hazards of products.

This equipment adopts a reasonable optical structure design to ensure the stability of image acquisition; it applies powerful deep learning technology to process images more intelligently; on the preform transport platform, a turntable structure is used to ensure the transport of preforms Stable; support the analysis of test data reports, which can help the management to understand the production situation in time. This equipment can help customers to complete a higher level of preform quality inspection and ensure the quality of the final product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!