Fully Automatic Visual Quality Inspection Machine For Liquid Leakages

Product backgound

In life, people's demand for beverages is essential. Therefore, the appearance of the beverage bottle also affects the concerns of every consumer. In order to reduce the number of unqualified beverage bottles, enterprises and manufacturers need to pay attention to the inspection process, and use the visual inspection system to check the high and low caps and liquid levels of beverage bottles. Waiting for the detection, we can solve this problem very well.

As beverages are produced, beverage manufacturers quickly fill bottles along conveyor belts, and to ensure customer satisfaction and protect brand reputation, bottles must be filled sufficiently and evenly. Detects and verifies liquid level, cap height and cap height in every bottle to reduce scrap and rework. In the bottling plant, product quality inspection uses visual inspection equipment to identify overfilled or underfilled bottles, uncapped caps, high caps or crooked caps, and unqualified beverage bottles are rejected by a reject device

Inspection details

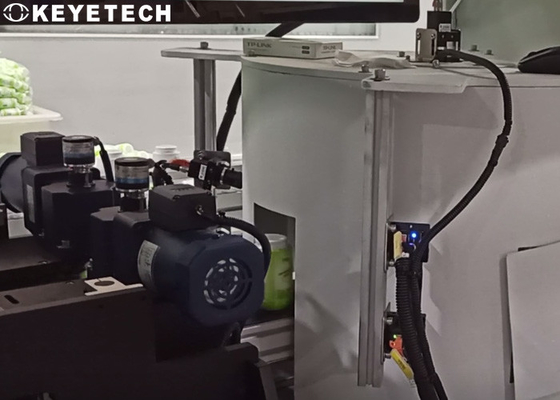

1. Install a customized visual inspection system on the beverage production line;

2. When the beverage bottle flows into the visual inspection station, by triggering the machine vision sensor to capture the beverage bottle picture and send it to the system, the system extracts and analyzes the taken picture and compares it with the setting to know whether the beverage bottle cap has a high cap, Low cover and high and low liquid level;

3. When it is detected that the beverage bottle cap has a high cap, a low cap or a high and low liquid level, the system sends a signal to the rejection device to give rejection treatment and alarm prompts.

Advantages of system

- 1. AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training

- Dataization: Independent database, save multiple samples, analyze non-good products, and retain history

- Multi-orientation: 360 ° comprehensive inside and outside the samples

- High precision: detection accuracy can be high

- Modularization, can flexibly increase or decrease the detection function according to customer actual needs

- Easy to operate: It is easy to operate and easy to maintain

- Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment

Equipment parameters

| Model.No |

Camera |

Detection range |

Test content |

Error |

Accuracy |

Speed |

Remark |

| KVIS-T-C-C06 |

1set |

bottle shoulder |

black spot,

impurity

|

>=0.5mm |

99.5% |

100-120/min |

All other foreign bodies are treated as black spots |

| 1set |

bottle lip |

flash |

|

black spot,

impurity

|

| deformation |

| 4set |

side printing

surface

|

missing print |

the font to disappear |

100% |

| blur |

>=0.5mm |

99% |

|

black spot,

impurity

|

99.5%

|

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!