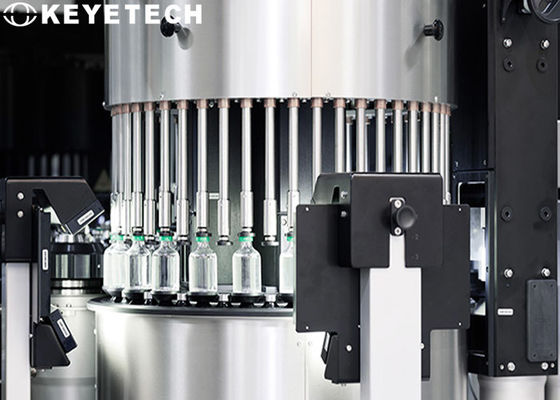

AI Algorithm Based Vision Inspection Machine for Empty PET Drinks Bottle

Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

Design Principle

The market demand for mineral water continues to increase, and customers have higher and higher requirements for product quality. Enterprises also pay more attention to brand building. More and more mineral water manufacturers have begun to use bottle cap liquid level coding detection systems.

OCR visual inspection of the bottle cap position, liquid level and coding of mineral water bottles replaces the traditional manual inspection, thereby rapidly improving production efficiency and product quality, and solving the low efficiency, slow speed, and missed inspection errors of human inspection. The disadvantages of high detection rate, as well as false detections and missed detections caused by uncertain factors such as subjectivity constraints of the testing personnel, achieve better online product testing

Configuration List

| Description |

Model |

Unit |

Q’ty |

Remark |

| Industrial Cameras |

KeyeTech |

Set |

8~10 |

China |

| Lenses |

KeyeTech |

Set |

8~10 |

China |

| LED Light Source |

KeyeTech |

Set |

3~5 |

China |

| Photoelectric Sensor |

SICK |

Pair |

1 |

Germany |

| Electromagnetic Valve |

SMC |

PC |

1 |

Japan |

| Industry Power |

Mean Well |

Set |

3 |

China |

| Main Control Board |

KeyeTech |

PC |

1 |

China |

| AI Computing Unit |

KeyeTech |

Set |

2 |

China |

| Pollution Filter |

KeyeTech |

Set |

1 |

China |

| HID Touch Screen |

AOC 21’ |

Set |

1 |

China |

| AI Algorithm System |

KeyeTech |

Set |

1 |

China |

| AI Cloud Platform |

KeyeTech |

Set |

1 |

China |

| Big Data Server |

KeyeTech |

Set |

1 |

China |

| Operation System |

Linux |

Set |

1 |

Finland |

System Advantage

1. AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training.

2. Dataization: Independent database, save multiple samples, analyze non-good products, and retain history.

3. Multi-orientation: 360 ° comprehensive inside and outside the bottle without dead corners for medical packaging bottle caps, bottle mouths, bottle bottoms.

4. High precision: detection accuracy can reach 99.5%.

5. Modularization, can flexibly increase or decrease the detection function according to customer actual needs.

6. Easy to operate: It is easy to operate and easy to maintain.

7. Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment.

Machining Process

Cooperation Partners

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

Delivery Time

The production cycle of the whole machine is expected to take 60 days. If additional inspection requirements are added or more adjustment needed, the time will be appropriately extended accordingly. After the equipment arrives at the customer's site, our company arranges after-sales personnel to complete installation and adjustment at the customer's site.

After Sales Service

- The seller should complete the creation and debugging of the product basic algorithm model before the equipment is shipped, also provide remote assistance after the equipment arrives at the customer site; and provide buyer with the factory data and operation manual of equipment.

- Daily operation and maintenance services: Our company provides free remote operation and maintenance online services. If you need to upgrade inspection algorithm, provide operational assistance, etc.

- Our company have regular offline training plan every year, so domestic and foreign clients can send their engineers to participate (at their own expense). Those who pass the exam can obtain an industry functional skills certificate.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!