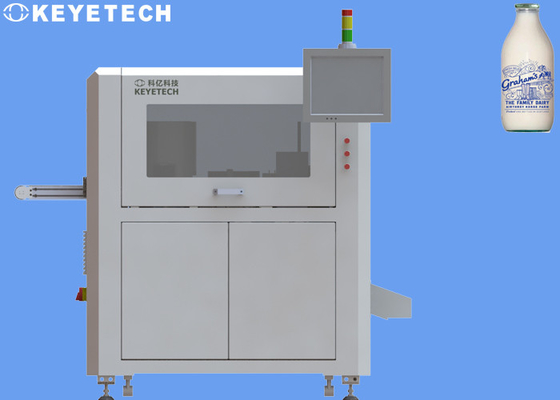

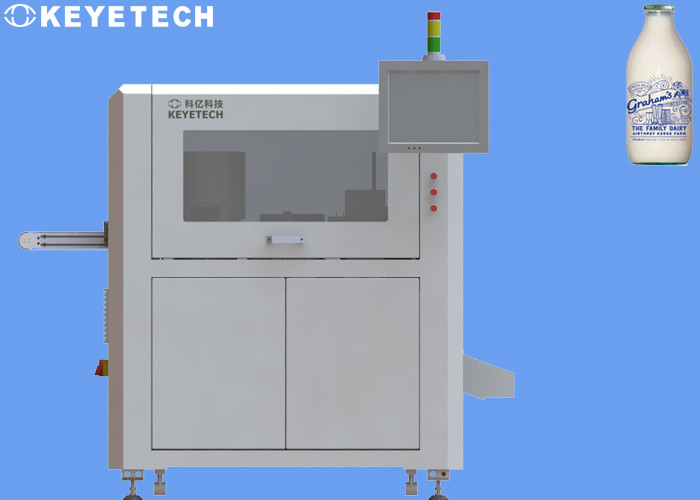

Special-shaped dairy bottle appearance defect detection equipment is a comprehensive detection equipment for the defects in special-shaped dairy bottles in the production process. Special-shaped dairy bottles are mainly designed according to consumers' preferences and their pursuit of new things. Many brands and businesses will also use the novelty of packaging to attract customers, so as to achieve the effect of drainage. However, since the special-shaped bottle itself is an irregular product, there may be defects and various defects in the product due to various reasons in production. Therefore, the manufacturer will graft professional visual inspection equipment according to the actual production needs. Comprehensive testing of products

Detection principle

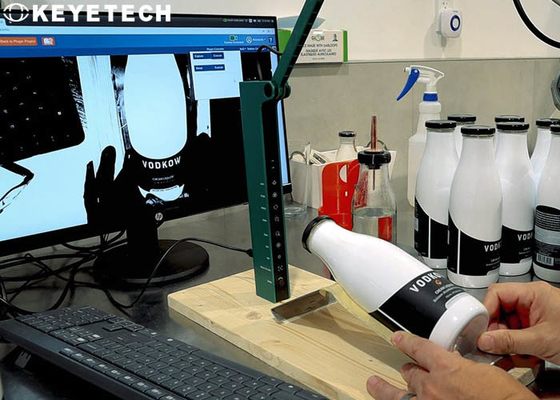

The special-shaped dairy bottle appearance defect detection equipment is connected to the front-end automation mechanism (which can be directly connected to the conveyor line, and the specific implementation method is to be determined according to the production site), and the special-shaped dairy bottle is stably and orderly transferred to a specific inspection station, and then all the products are detected by an industrial camera. The captured high-pixel image of the sample is transmitted to the image processing software, and the AI artificial intelligence algorithm detects and determines the good and bad products, and controls the corresponding pneumatic components to remove the bad products, and finally outputs the qualified products. The back-end conveyor platform of the testing machine can be docked Automated packaging mechanism.

Equipment overview

➢ Online high-speed detection, improve detection efficiency and accuracy, and reduce labor costs.

➢ Accurate identification of high-pixel industrial cameras, the number of cameras is designed on demand, the accuracy is 0.1mm, and the speed is 300 pieces/min (can be customized according to testing needs).

➢ Compatible with testing products of multiple specifications, saving costs.

➢ Detect and remove defects such as black spots, color difference, impurities, gaps, residual material, flash, bubbles, voids, deformation, uneven thickness and size of special-shaped dairy bottles.

| Name |

Special-shaped dairy bottle appearance defect detection equipment

|

Model |

Kvis-Sc02 |

| Software Algorithm |

Deep Learning |

Voltage |

Ac220/50Hz |

| Voltage |

200w |

Air Pressure |

Mpa |

| Transfer Method |

Lossless Delivery |

Detection Status |

Online Real-Time Detection |

| Detection Method |

High-Speed Industrial Camera |

Number Of Camera |

Depending on the specific situation |

Product advantages

- AI algorithm: high stability, can adapt to the disturbance of the environment and background; after training, it can automatically identify different defect samples.

- Dataization: independent database, save a variety of samples, analyze defective products, and keep historical records.

- Multi-directional: 360° all-round inspection without dead angle on the bottle body, bottle mouth, bottle bottom, and inside and outside of the bottle for special-shaped dairy products.

- Visualization: Real-time display of sample images, running status, real-time statistical inspection results and defective product defect classification information.

- High precision: The detection accuracy rate can reach 99.5%.

- Modular, can flexibly increase or decrease the detection function according to the actual needs of customers.

- Easy to operate: The equipment is easy to operate and easy to maintain.

- Safety: Made of medical-grade materials, it fully conforms to the production environment of medical supplies.

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!