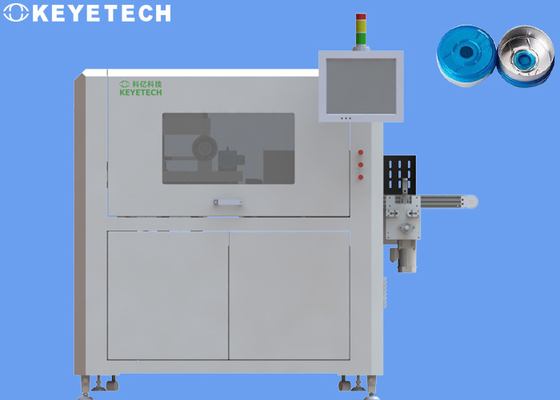

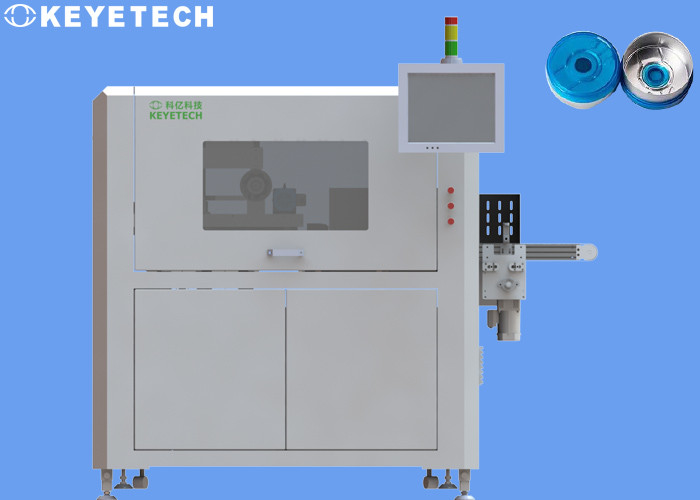

Visualizer Optical Inspection System for Plastic Bottles 360 Degree Detection

Inspection Object

As a medical bottle cap, the aluminum-plastic combination cap has a variety of specifications and is easy to open. It is widely used in medicine. In the sealing of bottled liquids such as antibiotics, injections, oral liquids, and infusions, the aluminum-plastic combination bottle cap also exerts its unique characteristics. Superiority. The aluminum-plastic composite cover has simple structure, low cost, good airtightness, and is more convenient to use. Aluminum-plastic composite caps have many advantages, such as stable torsion, which can reduce the opening time; strong resistance to tension and corrosion resistance, and these are the reasons why aluminum-plastic composite caps are widely used as medical bottle caps.

The pharmaceutical industry has always been the object of attention by most groups. Therefore, the testing of pharmaceutical packaging must be particularly strict. Keyi Technology has provided advanced technology for packaging testing in many pharmaceutical industries, and has also extensively matured testing. Share the system with more manufacturers who need testing equipment.

Inspection Standard

| Model |

Number of camera

|

Inspection scope

|

Inspection content

|

Detection precision

|

Accuracy

|

Capacity |

|

KVIS-MC

-SC10

|

1 set |

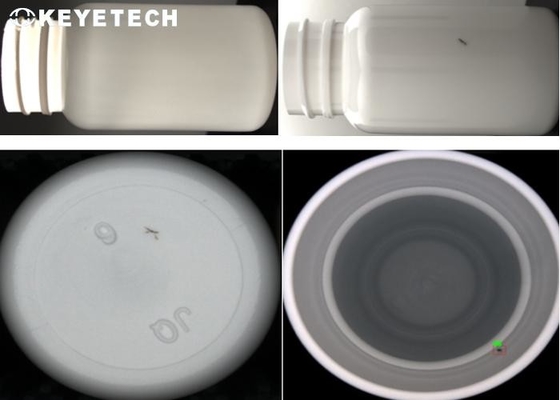

Concave area

|

Black spot,stains (color different)

|

≥0.2mm |

Qualified more than 96%

|

300 Pcs/mins

|

|

Wrong detecting rate less than 1%

|

| 1 set |

Top area

|

Black spot,stains (color different)

|

≥0.2mm |

Qualified more than 96%

|

|

Wrong detecting rate less than 1%

|

|

4 set

|

Side area

|

Black spot,stains (color different)

|

≥0.2mm |

Qualified more than 96%

|

|

Wrong detecting rate less than 1%

|

|

Printing missing

|

≥1.0mm |

Qualified more than 96.5%

|

|

Wrong detecting rate less than 1%

|

|

Injection incomplete

|

≥0.5mm |

Qualified more than 98%

|

|

Wrong detecting rate less than 0.8%

|

|

Sealing not good

|

≥1.0mm |

Qualified more than 95% |

| Wrong detecting rate less than 1% |

|

4 set

|

Ring area

|

Black spot, stains (color different)

|

≥0.2mm |

Qualified more than 96%

|

|

Wrong detecting rate less than 1%

|

|

Incomplete

|

≥0.5mm |

Qualified more than 98%

|

|

Wrong detecting rate less than 0.8%

|

Remark:

1. The grayscale contrast difference value of black spots and dirt defects must be greater than 40 to be effectively detected

2. The material needs to remain stable

3. Dust and other external factors will affect the algorithm detection, so maintain a dust-free environment

5. There is a blind spot in the bottle thread, and the bottle body and the inner wall of the bottle mouth cannot be detected

6. The lack of material, cracks, and flash detection are clearly visible to the human eye

7. The bottom of the bottle may be blocked by the rough edges of the bottle mouth when shooting, resulting in a blind spot on the bottom of the bottle

More About The Camera

Cooperation Partners

Our company have served many well-known enterprises such as Coca-Cola, P&G,Unilever,ALPLA,C'estbon, Nongfu Spring, etc., and has won praise from many users.

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!