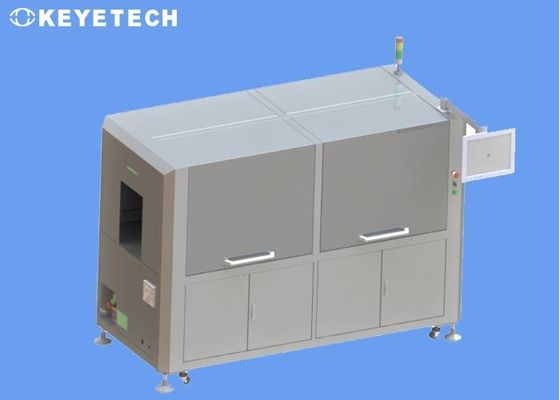

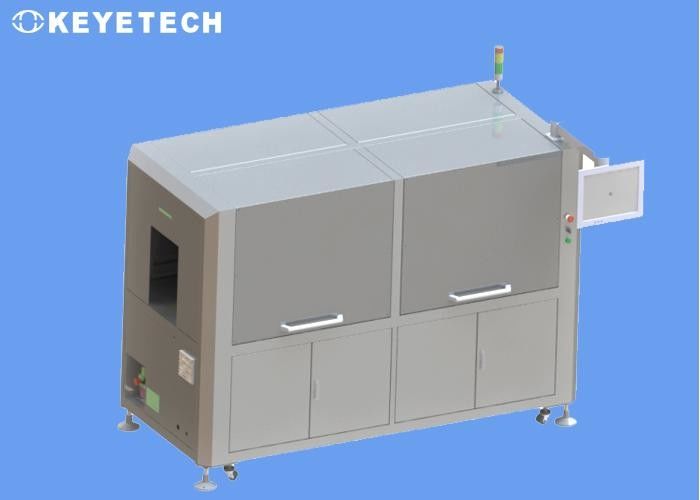

Automated AOI Vision System Machine for PET Preform Inspection and Sorting

System Features

| 1.AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training |

| 2.Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3.Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4.High precision: detection accuracy can be high |

| 5.Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6.Easy to operate: It is easy to operate and easy to maintain |

| 7.Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

Inspection principle

With small footprint space occupied, KY-PP has been designed to be easily installed offline to any new or existing injection molding machine of any manufacturer, in order to achieve a precise and immediate control of production. It includes an innovative and patented feeding device, developed with particular attention to the gentle treatment of preforms in order to avoid scratches, dents or any other type of damage. KY-PP is able to inspect the entire preform including the top seal, body, thread ring, injection gate, etc. at a speed of up to 24,000 preforms/hour, detecting product surface defects and defects visible by your eyes.

Hardware:

1) Camera: We use our own developed camera (the chip is from Japan), which has clearer image recognition and is more compatible with our own software.

2) Light source: We have a dedicated optical team to develop various light sources to adapt to the optical scene requirements of different industrial scenes.

3) Embedded computer: The KEYE team independently developed the embedded computer NPU computing box, which replaced the traditional PLC industrial computer; it is not afraid of sudden power outages and high temperature scenes, and can better adapt to the high temperature environment.

Software:

1) Algorithm: We use the latest AI deep learning algorithm. Most products only need a small amount of sample learning to complete a new product model; the machine can continuously learn some defects and good samples like the human brain, making the detection effect better and better.

2) Software: The latest KEYE V16.0 software can realize a variety of data statistics and human-computer interaction functions, and the touch screen operation is simpler.

3) KEYE cloud platform: The AI cloud platform can create its own cloud platform account for each customer, and the pictures of each training operation will be saved in its own account; even if the algorithm is lost due to software algorithms or other problems, all previous data can be retrieved through an independent cloud platform account. (KEYE team has technicians who regularly maintain this platform).

4) After-sales service: Provide long-term remote service, customers only need to keep the device in good network connection.

Delivery Time

The production cycle of the whole machine is expected to take 12-15 weeks. If additional inspection requirements are added or more adjustment needed, the time will be appropriately extended accordingly. After the equipment arrives at the customer's site, our company arranges after-sales personnel to complete installation and adjustment at the customer's site.

After Sales Service

- The seller should complete the creation and debugging of the product basic algorithm model before the equipment is shipped, also provide remote assistance after the equipment arrives at the customer site; and provide buyer with the factory data and operation manual of equipment.

- Daily operation and maintenance services: Our company provides free remote operation and maintenance online services. If you need to upgrade inspection algorithm, provide operational assistance, etc.

- Our company have regular offline training plan every year, so domestic and foreign clients can send their engineers to participate (at their own expense). Those who pass the exam can obtain an industry functional skills certificate.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!