Table: System operating conditions

| System dimension |

Designed according to the actual situation of the production line |

| Voltage |

220V 5A 50HZ |

| Environment humidity |

-20℃ - 60℃ |

| Ambient temperature |

Below 50% relative humidity |

| Compressed air |

0.5Mpa – 0.8Mpa Anhydrous |

| Power |

<1KW |

2. Equipment function

Detection functions

| Detection Indicator |

Detection of presence, error, and incompleteness of the date and serial number at the bottom of the bottled product |

| Detection speed |

100pcs/min |

| Detection range |

Bottom |

| Detection accuracy |

>0.1mm |

| Detection precision |

99.99% |

The system uses a high-speed industrial camera to take pictures of samples, and then compares the images with standard samples. The design principle detects the presence, error, and incompleteness of the third stage and serial code at the bottom of the primary package after filling. The equipment adopts a highly integrated detection and calculation module, which has the characteristics of compact space, convenient installation and deployment, accurate and fast detection, simple operation, and easy-to-use. It can be freely matched and installed at any position in the assembly line to ensure product quality.

Figure: Schematic diagram of system site layout

System functions

-Open and close the system detection function

-Adjustment of detection index parameters and accuracy.

-Template sampling and storage, sample detection information save and recall.

-Camera image calibration function

-The system displays real-time production information (qualification rate, total production, speed, etc.), historical production information browsing, export and save functions.

-Permission management based on the login account (such as general operation users disable parameter adjustment permissions)

-Operation and adjustment of the mechanical part of the system

(Such as open the transmission device, the adjustment of the air valve blow time, and the adjustment of the alarm signal)

-Additional functions that Party A needs to add

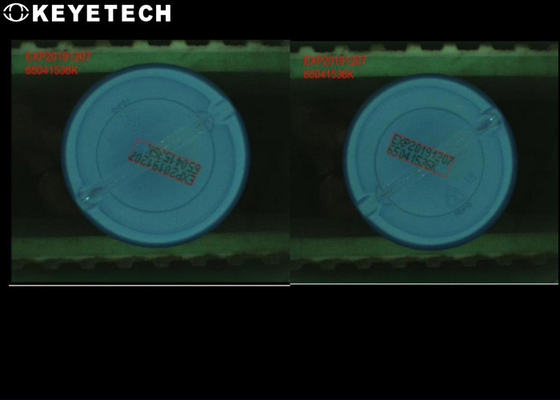

Sample detection pattern part example

The following patterns show some examples of defective sample patterns, including but not limited to the defects shown in the following images:

Figure : The red mark is the original data, and the red number is the data obtained after the camera analysis.

Advantages of system

- AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training

- Dataization: Independent database, save multiple samples, analyze non-good products, and retain history

- Multi-orientation: 360 ° comprehensive inside and outside the samples

- High precision: detection accuracy can be high

- Modularization, can flexibly increase or decrease the detection function according to customer actual needs

- Easy to operate: It is easy to operate and easy to maintain

- Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!