Product Description:

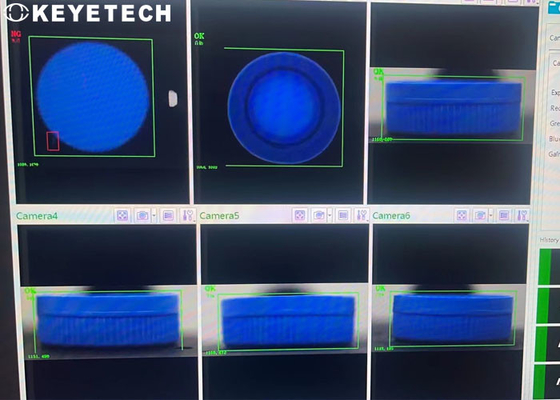

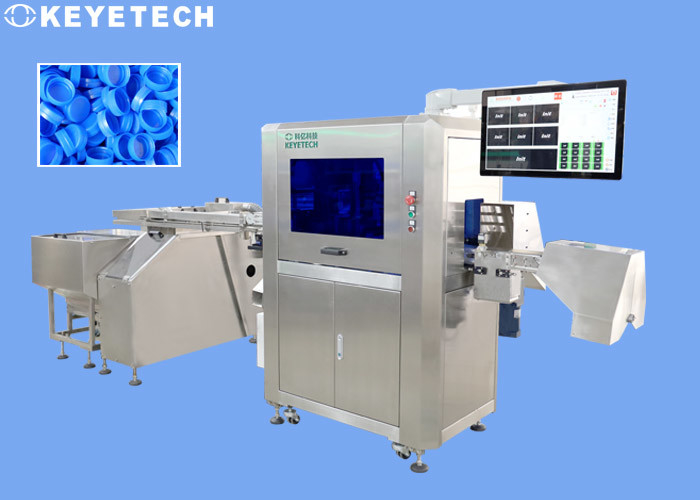

The Crown Inspection Platform is an innovative and effective closure inspection system, with a self-developed Closure Inspection Software that provides advanced capabilities for product inspection. The system offers a 360-degree inspection area with a high-definition touch screen for easy operation and control. It has a power range of 5 kW-7 kW to ensure efficient operation and provide reliable results. The platform is designed to inspect both caps and closures for quality assurance, ensuring that the product meets the highest standards of quality and performance. The system is easy to use and can detect any defects quickly and accurately, ensuring the product meets customer expectations. The platform is an ideal solution for manufacturers looking for a cost-effective and reliable inspection system.

Features:

- Cap Closure Checking System: Cap Inspection System

- Data Statistics: Support

- Inspection Speed: 600pcs/min - 2000pcs/min

- HMI: Have

- Warranty: 1 Year

- Display Screen: HD Touch Screen

- Closure Inspection Software: Included

- Lid Auditing System: Included

Technical Parameters:

| Parameter |

Value |

| Air Compressed |

0.5Mpa-0.8Mpa |

| Weight |

350kg |

| Inspection Speed |

600pcs/min - 2000pcs/min |

| Inspection Precision |

0.1mm |

| Power |

5kw-7kw |

| Voltage/Current |

Adapt To National Stardard |

| HMI |

Have |

| Application |

Cap Closure Inspection |

| Inspection Accuracy |

99.8% |

| Machine Material |

SS 304 |

Applications:

KEYE TECH KVIS-C Cap Closure Inspection System

Features:

- CE/ISO 9001/UL Certified

- Minimum Order Quantity: 1 SET

- Price: Negotiable

- Packaging Details: Plywood Carton

- Delivery Time: 6-8 Weeks

- Payment Terms: TT,L/C

- Supply Ability: 80set Per Month

- Machine Material: SS 304

- Inspection Precision: 0.1mm

- Display Screen: HD Touch Screen

- Application: Cap Closure Inspection

- Weight: 350kg

Application:

The KEYE TECH KVIS-C Cap Closure Inspection System is designed to provide a fast, accurate and reliable inspection process for all types of caps and closures, including beer and beverage, food, pharmaceutical and cosmetic caps. It features inspection software, a crown inspection platform and cover examining system, to ensure that the caps and closures meet the highest standards for quality and safety.

The system can identify and reject defective caps with precision accuracy up to 0.1mm, which is essential for ensuring that the products meet industry standards. The system is also equipped with an HD touch screen display which allows users to easily monitor and adjust settings as needed. It has a weight of 350kg and is constructed from stainless steel for maximum durability.

The KEYE TECH KVIS-C Cap Closure Inspection System is the perfect solution for any company looking to improve their production process and ensure their products meet the highest quality standards. It ensures that all caps and closures are examined thoroughly and accurately, reducing waste and improving efficiency.

Support and Services:

Cap Inspection System Technical Support and Services

Overview

Cap Inspection System provides comprehensive technical support and services to ensure our customers achieve maximum value from their technology investments. Our experienced support team is available to assist with any technical issues that arise during installation, operation, and maintenance of our systems.

Technical Support

Cap Inspection System offers 24/7 technical support to all of our customers. Our team of experienced engineers is available to answer technical questions, troubleshoot system problems, and provide guidance on best practices for product use.

Service and Maintenance

Cap Inspection System provides periodic maintenance services to ensure our systems are running optimally. Our experienced service technicians can assess the current condition of the system and perform any necessary maintenance or repairs. We also offer system upgrades and software updates to keep your system up to date and maintain its performance.

Training and Education

Cap Inspection System offers on-site and online training and education services to help our customers get the most out of their technology investments. Our experienced trainers can provide tailored instruction and guidance on best practices for system use, maintenance, and troubleshooting.

Packing and Shipping:

Packaging and Shipping for Cap Inspection System

The cap inspection system is packaged in a sturdy cardboard box with foam inserts to protect the system during shipping. The box is labeled with product information, including a description of the product, the company’s logo and contact information, and a barcode for tracking.

The cap inspection system is shipped via a reliable courier service to ensure that it arrives safely and on time. The shipment is tracked and insured to protect against loss or damage. All shipments are accompanied by the required documentation and paperwork.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!