Product Description:

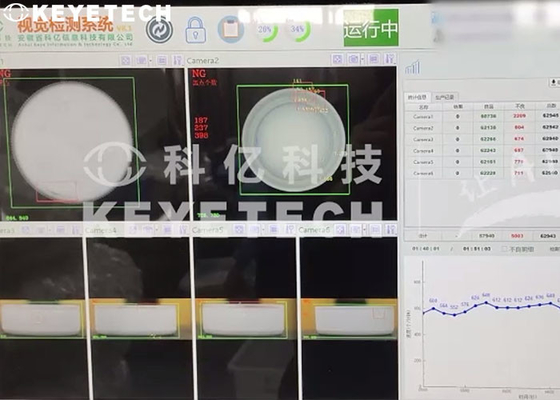

The Cap Inspection System is an advanced cover examining utility that is designed to adapt to national standards and provide high-precision inspection capabilities. It is equipped with a state-of-the-art HMI (human-machine interface) that makes it easy to use and highly efficient. The inspection accuracy of the system reaches up to 99.8%, and it offers a 360-degree inspection area for complete coverage. This high-performance system can be used for a wide range of cap closure inspection applications, making it an ideal choice for any businesses or organizations.

The Cap Inspection System is designed to provide the highest levels of accuracy and reliability. It features an advanced voltage/current system that can be adjusted to accommodate different national standards. The system's HMI is designed to be intuitive and user-friendly, making it easy to use and navigate. Additionally, the system's 360-degree inspection area allows for a full coverage of the cap closure, ensuring maximum accuracy and precision.

The Cap Inspection System is an ideal choice for businesses and organizations looking for a reliable and accurate cover examining utility. It is designed to provide the highest levels of accuracy and precision, while also being easy to use and navigate. The system also offers a 360-degree inspection area for complete coverage, making it an ideal choice for any cap closure inspection applications.

Features:

- Product Name: Cap Inspection System

- Machine Material: SS 304

- Display Screen: HD Touch Screen

- Voltage/Current: Adapt To National Stardard

- Inspection Speed: 600pcs/min - 2000pcs/min

- Air Compressed: 0.5Mpa-0.8Mpa

- Crown Inspection Platform: Automated Cap Inspection Platform

- Closure Inspection Software: Comprehensive Cap Closure Inspection

- Cap Closure Checking System: High Speed Cap Closure Checking System

Technical Parameters:

| Parameter |

Description |

| Warranty |

1 Year |

| Display Screen |

HD Touch Screen |

| Inspection Depth |

Deep Inspection |

| Camera Brand |

KEYE OEM |

| Inspection Precision |

0.1mm |

| Weight |

350kg |

| Inspection Accuracy |

99.8% |

| Inspection Area |

360 Degree Inspection |

| Machine Material |

SS 304 |

| Application |

Cap Closure Inspection |

| Crown Inspection Platform |

Cap Closure Checking System |

| Cap Closure Checking System |

Cap Closure Checking System |

Applications:

KEYE TECH Cap Closure Checking System KVIS-C

KEYE TECH's Cap Closure Checking System KVIS-C is a reliable and advanced closure inspection software made in China. The system has passed CE/ISO 9001/UL certifications and comes with minimum order quantity of 1 SET with a negotiable price. The system is packed in a Plywood Carton and the delivery time is 6-8 weeks. Payment terms are TT and L/C. It has a supply ability of 80set per month. The inspection precision is 0.1mm with data statistics support. Air compressed is 0.5Mpa-0.8Mpa. The display screen is HD touch screen and it has deep inspection depth.

Support and Services:

Cap Inspection System Technical Support and Service

The Cap Inspection System provides technical support and service to users of the system. Our team of experts is available 24/7 to help you with any technical issue you may have. We provide assistance with:

- Hardware setup

- Software installation and configuration

- System maintenance and troubleshooting

- Data analysis and reporting

- Product upgrades

We also offer a comprehensive training program to ensure users are able to get the most out of their Cap Inspection System. We provide both on-site and online training courses to help you become an expert in the system.

If you have any questions or need assistance, please don't hesitate to contact us. Our team of experts is here to help you get the most out of your Cap Inspection System.

Packing and Shipping:

Packaging and Shipping

The Cap Inspection System comes in a durable cardboard box that is designed to protect the system during transit and storage. The box includes foam inserts which help to keep the components of the system in place, ensuring that items do not suffer any damage during shipping.

The box also includes an instruction manual which provides users with information on how to install and use the system. The box is designed to fit through standard doorways and can be shipped to customers across the world.

For customers who require a more secure method of shipping, the system can also be shipped via courier or air freight. This will ensure that the system arrives at its destination in perfect condition.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!