Company Profile:

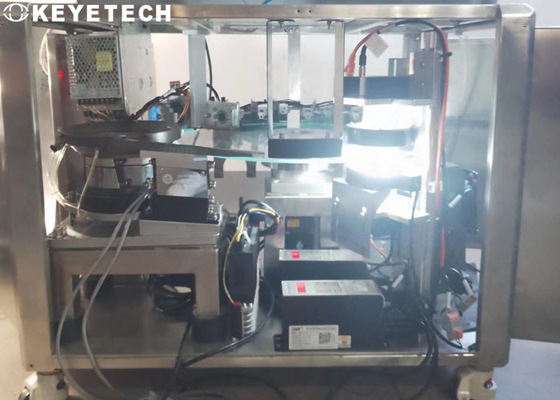

Keye Technology relies on the Keye Laboratory of Pattern Recognition of the University of Science and Technology of China, and has a high-level doctoral R&D team covering the entire technology chain of optics, mechanics, electricity, computing and software.

Through the project practice in the fields of packaging containers, 3C, medicine, textile, food, etc., the KVS-AI software and hardware platform has been created, so that AI technology can be transformed into real productivity. We provide visual imaging, algorithm computing power and automatic control AI system solutions for various sub-industries.

Through the project practice in the fields of packaging containers, 3C, medicine, textile, food, etc., the KVS-AI software and hardware platform has been created, so that AI technology can be transformed into real productivity. We provide visual imaging, algorithm computing power and automatic control AI system solutions for various sub-industries.

System Features:

| 1.AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training |

| 2.Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3.Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4.High precision: detection accuracy can be high |

| 5.Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6.Easy to operate: It is easy to operate and easy to maintain |

| 7.Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

Inspection Details:

Inspection Theory

The product is stably and orderly transmitted to the KEYE vision inspection machine, and the high pixel sample images captured are transmitted to image processing software through customized LED light sources and HD industrial cameras. Based on big data, AI algorithms are analyzed and compared, and the system automatically determines defective and good products. The corresponding pneumatic components are controlled to eliminate defective products online, and the good products are counted and boxed to complete product inspection.

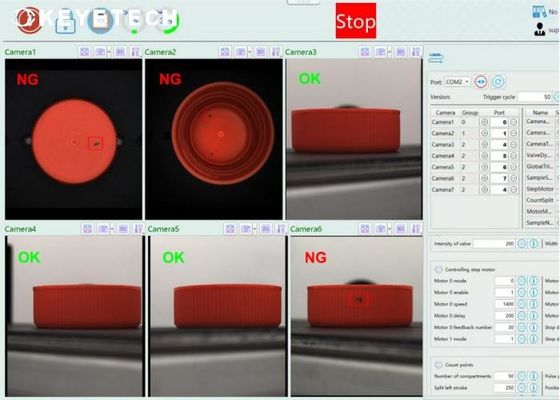

** The process of camera inspection system:

| Camera Station |

Inspection Content |

| Station1 |

CAM1 used to check cap flat side defect issue |

| Station2 |

CAM2 used to check cap concave side defect issue |

| Station3 |

CAM3/4/5/6 used to check cap outer sidewall defect issue |

Software Functions:

- Enabling and disabling the system detection function

- Detection index parameters and accuracy adjustment

- Statistics of the inspection details and data export in EXCEL format.

- Template sampling and saving, storage and retrieval of sample information

- Camera screen calibration function

- Real time production information display of the system (qualification rate, total output, speed, etc.), browsing of historical production information, export and storage functions

- Manage permissions based on login account (example, disabling parameter adjustment for general operation users)

- Operation and adjustment of the mechanical part of the system (If the transmission device is turned on, adjust the alarm signal)

Support and Services:

Grain Analyzer Technical Support and Services

At Grain Analyzer, we are dedicated to providing reliable technical support and services to our customers. We offer a wide range of services, including:

- Troubleshooting and diagnosing technical issues.

- Software updates and installation.

- Hardware repair and maintenance.

- Product registration and setup.

- Data and security monitoring.

- Data backup and recovery.

We also provide comprehensive technical documentation and user guides. If you need additional support or have any questions, please contact us at [insert contact information].

Packing and Shipping:

Packaging and Shipping

Grain Analyzer is packaged with two components: the main unit and the power supply. The main unit is securely placed in a foam-lined cardboard box, and the power supply is packaged separately. Both components are shipped with bubble wrap and placed in another cardboard box. The box is labeled with the product name and all necessary shipping information.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!