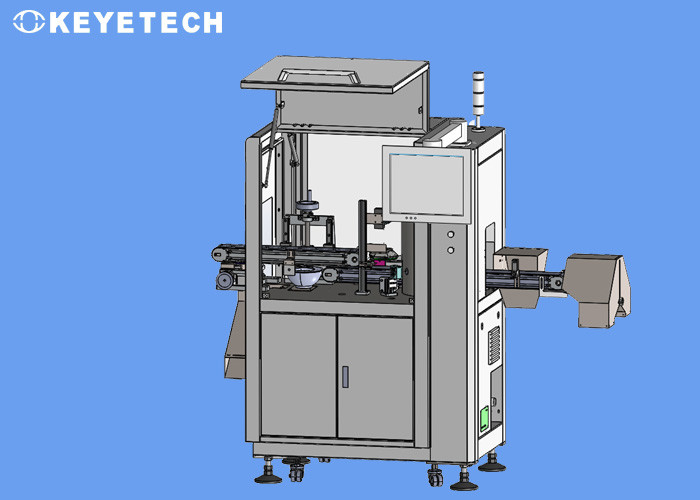

Crown Cap Closures Detection System With Linear Array Camera Inspection

Inspeciton details

| Model |

number of cameras |

inspection range |

Inspection |

Inspection precision |

accuracy |

capacity |

|

KVIS

-SC11

|

1pcs |

Inside area |

Contamintion |

≥0.25mm |

99% |

400 pcs per mins |

| Deformation |

≥2.0mm |

99% |

| 1pcs |

Inside area |

Cavity number reading

(There is no occlusion and interference on the cavity numbers, and there are spacing between the numbers )

|

- |

99.99% |

| 1pcs |

Top area |

Contamintion |

≥0.25mm |

99% |

|

COLOR DIFFERENCE

( The gray value difference is greater than 40)

|

- |

99% |

| 4pcs |

Outside area |

Contamintion |

≥0.25mm |

99% |

| MISSING COMPINENTS |

≥1.0mm |

99% |

| Defects on the lip |

≥1.0mm |

99% |

| Defects at the hinges and joints (obvious fracture, and the angle between the raised part and the surface is greater than 45°) |

≥2.0mm |

99% |

| The gap of the ring slitting oversized, deformed |

≥1.0mm |

99% |

| Sealing elements |

≥1.0mm |

99% |

| 4pcs |

The area of inner wall side |

Contamintion |

≥0.25mm |

99% |

|

Damaged pull taps

|

≥1.0mm |

99% |

Inspection principle

In order to ensure the quality of caps in the production process, defect detection is essential. However, due to the limitations of manual detection, the detection results are inaccurate, and the detection efficiency is difficult to improve. At this time, machine vision is needed for detection, and the accuracy rate far exceeds that of human eye detection. At the same time, the subjective factor of the inspector can be excluded, and the reliability is higher. Therefore, the replacement of human eye detection by machine vision detection will be an inevitable trend in future development.

Bottle cap defect detection requirements

The main inspection items include: bottle cap breakage detection, bottle cap height detection, visual inspection of bottle mouth defects, liquid level detection, and bottle label detection. Compared with traditional human eye inspection, machine vision inspection has the advantages of high accuracy, high efficiency, good continuity, inspection and report generation.

Defect solutions

Keyi Technology AI image visual inspection, according to product characteristics, customer inspection needs, make customized inspection solutions. Collect, label, and train the optimized model for bottle cap samples before detection, and deploy the model according to the actual needs of customers; during the detection process, through uniform illumination, industrial cameras take pictures and identify its appearance, and the software system classifies and decides on it.

When the bottle caps to be tested enter the detection area through the cap sorting machine, the light source and the camera are triggered to take pictures and identify them. The software system will classify and make decisions on the bottle caps according to the trained model. NG, issue a rejection order; qualified products are displayed as OK, and they are counted and binned.

Our advantages

- 1. AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training

- Dataization: Independent database, save multiple samples, analyze non-good products, and retain history

- Multi-orientation: 360 ° comprehensive inside and outside the samples

- High precision: detection accuracy can be high

- Modularization, can flexibly increase or decrease the detection function according to customer actual needs

- Easy to operate: It is easy to operate and easy to maintain

- Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!