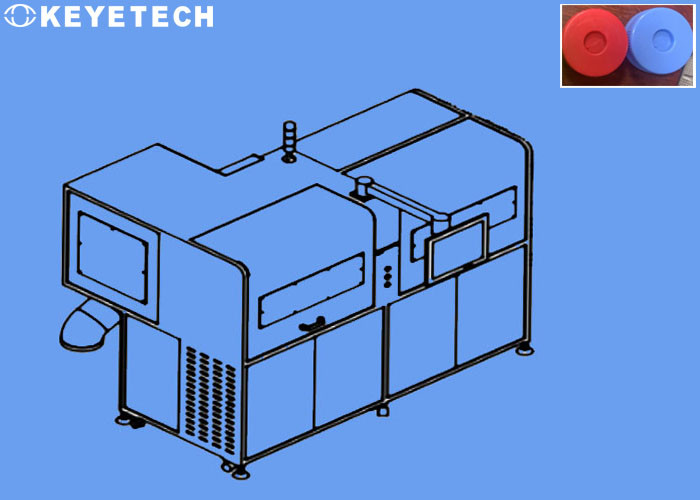

AOI Cap Inspection System - Reliable Defect Detection Machine

| Item |

AOI Cap Inspection System - Reliable Defect Detection Machine |

Main Material |

Stainless steel |

| Weight |

500kg |

Size |

4250*1650*1860mm |

| Software Algorithm |

Deep Learning |

Voltage |

Ac220/50Hz |

| Current |

4kw |

Air Pressure |

0.5-0.8Mpa |

| Transfer Method |

Lossless Delivery |

Detection Status |

Online Real-Time Detection |

| Detection Method |

High-Speed Industrial Camera |

Number Of Camera |

10 |

Company Profile

Anhui Keye Information Technology Co., Ltd. (hereinafter referred to as Key Technology) was established in 2011. It is a national high-tech enterprise focusing on applying AI technology to the industrial field. Provide visual imaging, algorithm computing power and automatic control AI system solutions for various sub-industries.

Keye AI visual inspection overall solution adopts the world's top AI algorithm, equipped with visual analysis software and lighting, imaging and acquisition processing modules, which has the advantages of small sample size, strong generalization ability and rapid deployment. At present, the products are used in many industries such as food, alcoholic beverages, dairy products, pharmaceuticals, cosmetics, and daily chemicals.

Inspection details

The solution uses 10 sets of high-resolution industrial cameras and high-performance strobe light sources to conduct all-round visual inspection for the appearance defects of paper cups. The single-line inspection speed is 500 pieces/min. The equipment can run all day long, and unqualified products can be checked online Automatically culled.

The whole set of testing equipment includes mechanical parts, visual electronic hardware and testing system software. The entrance and exit of the testing machine can be connected with the upstream and downstream equipment conveyor lines on site.

Inspection standards

| Item |

Camera |

Position |

Inspect |

Precision |

Accuracy |

Speed |

| KVIS |

1 |

cap bottom |

black sopt,dent&bulge,color difference,etc |

>0.5mm |

99% |

500pcs/min |

| 1 |

cap top |

| 4 |

inner side |

| 4 |

outer side |

Inspection notice

For defect features such as black spots and bubbles, the gray value contrast difference corresponding to the detection index must be greater than 30, which can be effectively detected. If the sample has transparent oil stains or light-colored black spots, and the gray value contrast difference is low (less than 30), the detection effect cannot be achieved.

Due to the different complexity of the structural features of different products, in actual application, there will be a certain area of detection blind area in the overlapping area of the plane lens imaging structure, and the image acquisition cannot reach the range of this blind area, so it cannot be effectively detected.

Company profile

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

** Our company have served many well-known enterprises such as Coca-Cola, P&G,Unilever,ALPLA,C'estbon, Nongfu Spring, etc., and has won praise from many users.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!