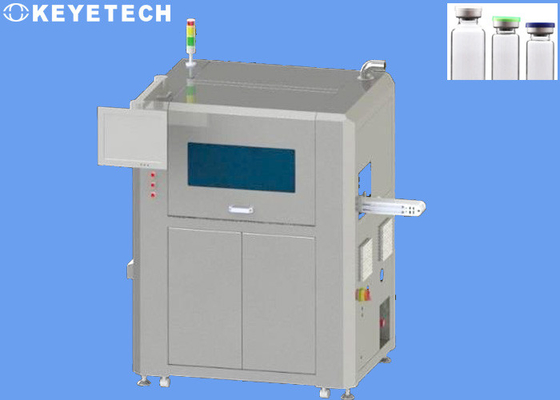

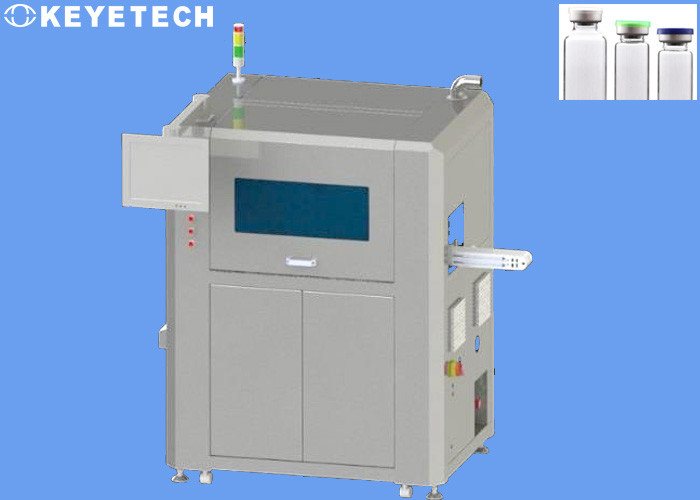

Pharmaceutical Packaging Solutions Vial Appearance Defect Detection Equipment

Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

| Item |

Pharmaceutical Packaging Solutions Vial Appearance Defect Detection Equipment |

Main Material |

Stainless steel |

| Weight |

500kg |

Size |

4250*1650*1860mm |

| Software Algorithm |

Deep Learning |

Voltage |

Ac220/50Hz |

| Current |

4kw |

Air Pressure |

0.5-0.8Mpa |

| Transfer Method |

Lossless Delivery |

Detection Status |

Online Real-Time Detection |

| Detection Method |

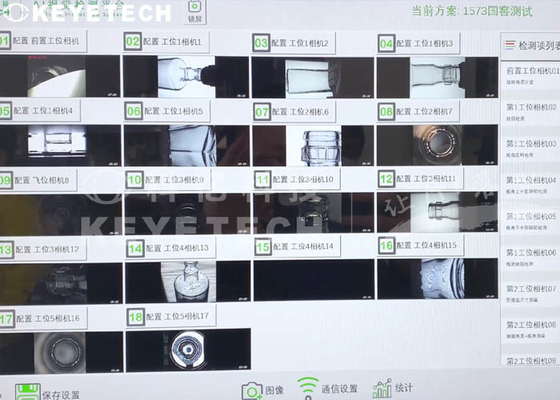

High-Speed Industrial Camera |

Number of Camera |

Depending on the specific situation |

Inspection principle

The Vial Vial Appearance Defect Inspection Equipment is an all-round inspection equipment for the defects that appear in the production process of vials. Vials are generally used for the packaging of vaccines, biological agents, powder injections, freeze-dried and other drugs, and are widely used in the biomedical packaging industry.

Product quality is controlled by most scientific research laboratories, and there are higher requirements for its quality. However, due to the special manual inspection of the vial material, it may cause secondary damage to the bottle body, so enterprises can introduce advanced visual inspection Equipment to achieve quality control.

Vision solutions

The vial appearance defect detection equipment is connected to the front-end automation mechanism (it can be directly connected to the conveying line, the specific implementation method is to be determined according to the production site), and the vials are stably and orderly transported to the specific inspection station.

The high-pixel sample image captured by the industrial camera is transmitted to the image processing software, and the good and defective products are detected and judged by the AI artificial intelligence algorithm, and the corresponding pneumatic components are controlled to eliminate the defective products, and finally the qualified products are output, after the inspection machine The end conveying platform can be connected to the automatic packaging mechanism.

Features of KVIS system

- The ability to track and monitor results through an advanced human-machine interface

- Optical technology that is powerful enough to capture even minute defects, without false rejects

- A thorough inspection of sidewalls, base, finish, and thread

- The ability to keep up with high-speed lines

- Fast changeover to reduce downtime on the line

- Reduction of product waste and false rejects

After-sale Service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!