Linear Vibration Feeds Full Automactic Visual Inspection Machine For Capacitors

| Equipment parameters |

| Name |

Electrolytic capacitor appearance inspection machine |

Model |

KVIS-DR |

|

Dimension(mm)

L*W*H

|

2590* 800*1850(Length does not include vibration plate system) |

Voltage |

AC220/50HZ |

| Power |

3KW |

Pressure |

0.4-0.7Mpa |

| Conveying method |

Vibrating plate feeding, non-destructive conveying |

Inspection method |

Online real-time inspetection |

| Camera type |

High-speed industrial camera |

Number of cameras |

14 sets of camera |

| Algorithm |

Deep learning |

Compatible product size |

Φ8-10,12,13 |

| Speed |

400~600/min |

Inspection scope |

Poor appearance, poor size, mixed specifications, etc. |

| Rejection method |

High-speed automatic rejection |

|

|

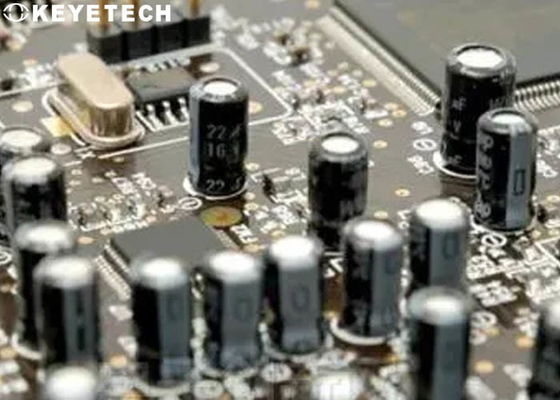

Product background

Capacitors are electrical components and indispensable basic components in electronic circuits. Capacitors are widely used in electronic appliances, machinery, medical treatment, transportation, communications, instrumentation, aerospace and other fields. The demand for such components is extremely large, and a single batch can produce millions of pieces, and each circuit board will use dozens to thousands of pieces; although the components are small, their quality requirements are very strict. A damaged capacitor may cause the entire circuit board to be scrapped. If the capacitor uses manual quality inspection, it will undoubtedly require a large number of skilled workers, and the speed is slow, and the accuracy is difficult to guarantee.

Machine vision capacitance testing equipment is the most suitable choice. The equipment can efficiently and quickly detect the appearance defects of capacitors, automatically reject defective products, and improve product quality. The capacitor appearance analyzer produced by KEYE TECH has a detection efficiency of 500-600pcs/min under the premise of ensuring high accuracy. While improving product quality, it can also reduce labor and reduce enterprise production costs.

Features of system

High efficiency: speed up to 400-600 per minute

High precision: Under the condition of 2% defective products, the detection accuracy is 99.5%, and the false rejection rate is only 0.5%

Easy to operate: the operator only needs 10 minutes of training to operate the equipment

Reduce customer production costs: High-speed, all-round detection technology greatly shortens the production cycle of the enterprise, reduces labor costs, and thereby reduces production costs

Inspection principle

The materials are arranged by vibrating plate, Linear vibration and non-destructive conveying, and the capacitance is stably and orderly transferred to the specific inspection station, and then the high-pixel sample image captured by the industrial camera is transferred to the image processing software. After the system analyzes and processes, it judges good and defective products, and controls the corresponding pneumatic components to eliminate the defective products, and finally collects qualified products.

Specific functions

- Trigger the light source strobe

- Trigger the camera to take a photo

- Trigger the solenoid valve to jet off waste products

- Control the belt speed

- Emergency treatment for system jams or similar situation

- Trigger the alarm light signal

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!