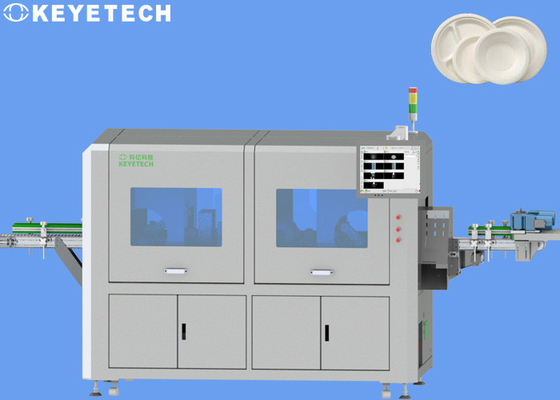

Paper Round Plate Visual Inspection System Surface Defects Detector

| Item |

Paper Round Plate Visual Inspection System Surface Defects Detector |

Main Material |

Stainless steel |

| Weight |

500kg |

Size |

4250*1650*1860mm |

| Software Algorithm |

Deep Learning |

Voltage |

Ac220/50Hz |

| Current |

4kw-5kw |

Air Pressure |

0.5-0.8Mpa |

| Transfer Method |

Lossless Delivery |

Detection Status |

Online Real-Time Detection |

| Detection Method |

High-Speed Industrial Camera |

Number Of Camera |

Depending on the specific situation |

Overviews of inspection

Disposable dinner plates have greatly facilitated people's lives. Today, in order to save costs, almost all businesses start to use disposable dinner plates, and they will bring some unique patterns or print the brand logo. With a large number of market demands, consumers' experience directly affects the strict requirements of merchants on packaging quality.

In order to increase production efficiency, the manufacturer changed the time-consuming and labor-intensive manual inspection, and chose to graft intelligent inspection equipment to its own production line. Keye Tech has been engaged in the packaging inspection industry so far, and has made a lot of inspection equipment related to dinner plates. , there are very good professional examples in the industry, which can use big data intelligent algorithms to update detection data in real time and discover possible problems in the production line in time.

Inspection details

By docking with the loading and distributing mechanism, the products are transported to the specific inspection station in a stable and orderly manner in a face-up manner, and then the high-pixel sample images captured by the industrial camera are transmitted to the image processing software for comparison with standardized samples After the analysis, the good and bad products are judged, and the corresponding pneumatic components are controlled to remove the bad products, and finally the qualified products are output, and the rear-end conveying platform of the testing machine can stack the receiving material.

The software will open the sample comparison standard, and the production personnel at the customer site can control the comparison accuracy and choose the most suitable accuracy standard for their own production conditions, so as to control the defective rate.

Application of cameras

Our design scheme adopts 3 sets of high-pixel industrial cameras and high-performance strobe light sources to conduct all-round visual inspection for the appearance defects of dinner plate products. The inspection speed is 150 pieces/minute, and the equipment can realize 7*24 hours all-weather Running, unqualified products can be automatically removed online.

The whole set of testing equipment includes mechanical parts, visual electronic hardware and testing system software. The entrance and exit of the testing machine can be integrated with the automation mechanism (see the design drawings for details of the connection method), and can be connected with upstream and downstream production according to the specific production needs of the customer's site equipment.

Company profile

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!