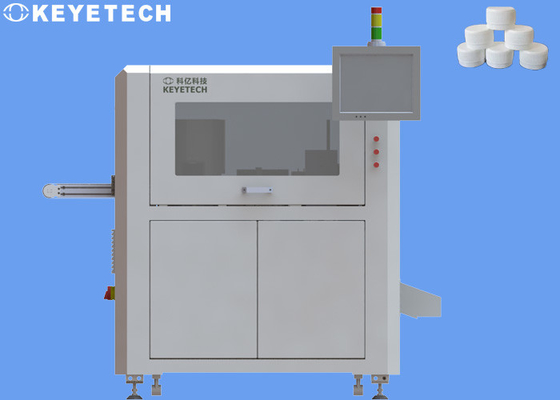

Automated Optical Inspection Machine For Plastic Cap Closures

Inspection Standard

| Model |

Number of camera |

Inspect |

Inspection content |

Precision |

Speed |

| KVIS |

1 set |

Concave area |

Black spot,stains (color different) |

≥0.2mm |

300 Pcs/mins |

| 1 set |

Top area |

Black spot,stains (color different) |

≥0.2mm |

| 4 set |

Side area |

Black spot,stains (color different) |

≥0.2mm |

| Printing missing |

≥1.0mm |

| Injection incomplete |

≥0.5mm |

| Sealing not good |

≥1.0mm |

4 set |

Ring area |

Black spot, stains (color different) |

≥0.2mm |

| Incomplete |

≥0.5mm |

Inspection principle

The traditional manual inspection method has been difficult to meet the inspection needs of the bottle cap production process in the beverage, pharmaceutical and other industries. Quality control is the core competitiveness of modern manufacturing manufacturers. To ensure high-quality products, modern intelligent testing equipment is inseparable. The introduction of automated visual inspection machines for bottle caps is an essential choice for bottle cap production and inspection, and it is also the key to winning the market.

Inspection details

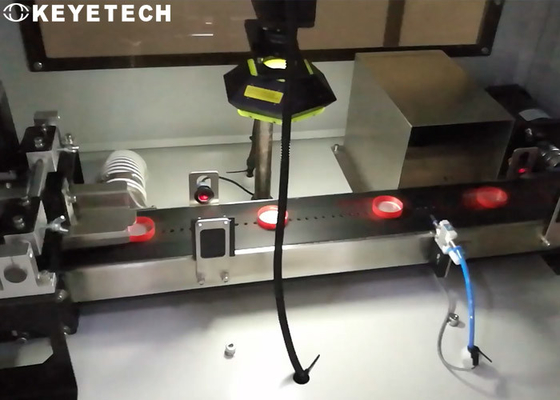

The bottle cap inspection machine adopts machine vision technology to measure, judge and analyze the detected object with the machine instead of the human eye. To a dedicated image processing system, according to pixel distribution, brightness, color and other information, converted into digital signals.

The image system performs various operations on these signals, extracts the characteristics of the target, and then controls the action of the equipment on the spot according to the judgment result of the set standard, and the unqualified products are automatically rejected. In this way, the detection process can realize automatic feeding, automatic detection, automatic sorting, unloading, packing, packing and other system operations, and the detection work is more efficient and fast.

What defects can the bottle cap inspection machine detect?

- 1. Detect the deformation, flash, black spot, lack of material, gasket and other defects of the bottle cap and remove them online;

- 2. Applicable to all kinds of bottle caps: anti-theft caps, combined caps, butterfly caps, Epoxy caps, aluminum-plastic caps, etc.;

- 3. Optional 2-8 cameras, top surface, bottom surface, inner surface, multi-angle, no dead angle full-range detection;

The traditional manual inspection method, regardless of speed or efficiency, is difficult to keep up with the needs of mass production, and the inspection results are easily affected by the emotions and energy of the inspectors. The bottle cap inspection machine using machine vision inspection technology can perform real-time online automatic detection of bottle cap appearance defects, which is fast, efficient, stable and reliable.

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!