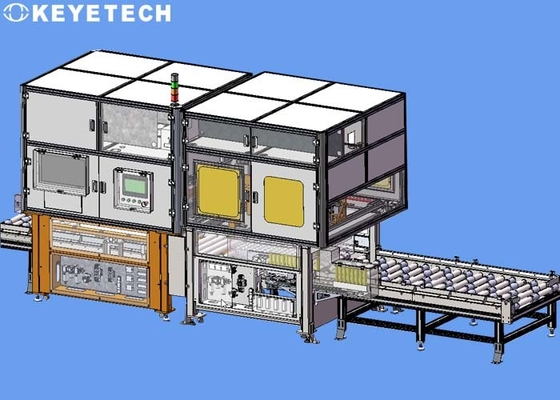

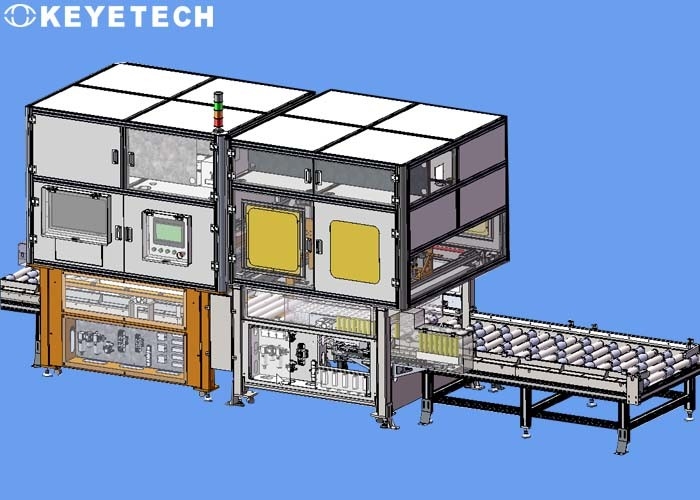

New Energy Visual Inspection Machine For Li-Ion Battery Surface Checking

System Operating Parameters:

| System operating parameters |

| System size |

See design drawings for details |

Voltage and current |

220V 20A 50HZ |

| Equipment Power |

5.0-6.0kw |

Compressed Air |

0.5~0.8Mpaclean And Oil-Free |

| Ambient Temperature |

-20℃ ~ 60℃ |

Environment Humidity |

Below 50% Relative Humidity |

Inspection principle

Lithium-ion batteries have developed rapidly in recent years, but due to the constraints of technology and production conditions, there is a big contradiction between production capacity and demand. At present, the detection method used for lithium battery pole pieces is basically full manual visual inspection. The way. However, there is a high probability of many defects after the pole pieces are processed. All pole pieces must be inspected before the battery lamination assembly, and the waste products, defective products (can be used after processing) and genuine products are identified and stored and processed separately.

The reliability, stability and efficiency of manual detection cannot be effectively controlled, and the labor cost during the epidemic is currently high, and the labor-intensive production directly restricts the low-cost production of lithium batteries. Due to the continuous shortage of human resources, labor costs remain high, and this status quo will continue, and the cost pressure of lithium batteries has not been released.

Inspection details

- The improvement of production automation will improve this situation. In order to further reduce production costs and improve product quality, we have designed and developed a lithium battery pole piece machine vision inspection equipment to speed up the automation level of the lithium battery industry.

- Before the pole piece is coated and baked, the coating width is detected online in real time with machine vision, the measurement data is provided in time, and the coating width is corrected in real time.

- Due to the difference in the coating width in the light map, the visual grasping edge does not fit, so the width of the coating changes. In the visual inspection, the result can be given quickly and accurately in real time and the OK/NG can be judged.

- The popularization of machine vision inspection equipment has subverted the existing detection method using manual visual inspection. Instead, machine vision automatic inspection is adopted, which speeds up the efficiency of industrial automation, reduces the cost of enterprises, and relatively improves the inspection effect. The inspection effect is stable and greatly improved. Improve the quality of products put on the market.

Camera position

The system uses four cameras, the first camera is used to detect the width of copper tabs on the front of the battery pack, the width of copper tabs, the detection of copper tabs entering the shell, the width of aluminum tabs, the width of aluminum tabs, the width of aluminum tabs, and the width of aluminum tabs. Case detection, the width of the polar tabs, the second camera is used to detect the width of the front side seal of the battery pack, the presence or absence of the bottom seal, the detection of the sealing surface, and the detection of pinching.

And the third camera is used to detect the width of the copper tabs on the back of the battery pack. , copper tab width, copper tab into the shell detection, aluminum tab glue width, aluminum tab width, aluminum tab into the shell detection, two tab width, the fourth camera is used to detect the width of the back side seal of the battery pack, the bottom Detection of seal presence, sealing surface detection, and pinch detection. The four cameras open up threads respectively, start the thread when detection is required, and suspend the thread when detection is not required.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!