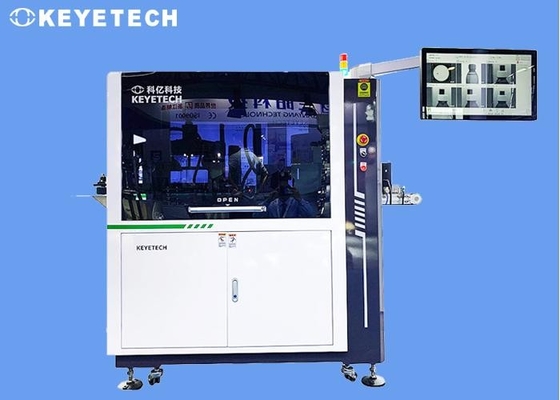

High Tech CCD Visual Inspection System Reduce Time And Labor Cost

Equipment features:

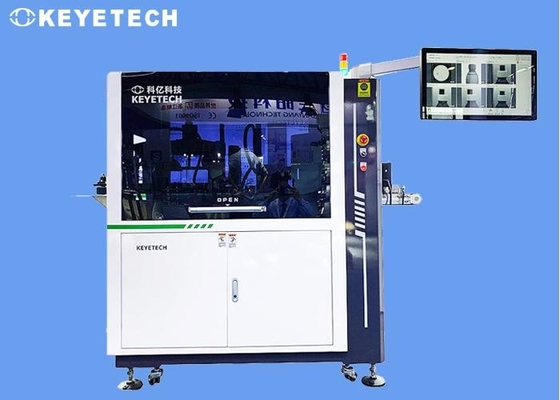

| 1. AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training |

| 2. Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3. Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4. High precision: detection accuracy can be high |

| 5. Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6. Easy to operate: It is easy to operate and easy to maintain |

| 7. Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

Inspection principle

Appearance defect detection is a very important link in the manufacturing process. From small parts to complete machines, a computer has to undergo hundreds of different appearance defect inspections.

We all know that the detection of appearance defects requires high labor costs, and the detection efficiency of workers is lower than that of machines. There are also a series of problems such as visual fatigue, poor mentality, personnel training, and high personnel turnover. Factories bear great risks.

**The factory has started to replace manual labor with machine vision inspection, but the machine still cannot 100% meet the inspection needs of all enterprises:

1. It is difficult to detect defects inside the product

2. Unable to detect completely irregular complex product images

3. The anti-interference ability is poor, and it is easy to cause problems such as false detection and missed detection.

4. Uninput defect detection instructions cannot be identified independently

5. High requirements for the detection environment, etc.

Advantages of visual inspection

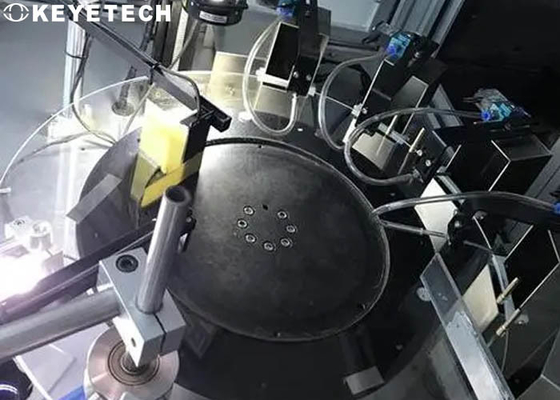

1)High detection accuracy and fast detection efficiency:CCD visual inspection equipment uses machine control according to the system, with small error and high detection rate.

2)Wide detection range to detect cosmetic defects and dimensional measurements:The multi-station inspection method can accurately measure the outline, specifications, appearance defects, product aspect ratio and other performance parameters of the product to be inspected at one time.

3)Improve product quality and error rates:Vision inspection equipment is based on system control, which can distinguish good products from bad products through automatic inspection technology, and then automatically place them in different parts.

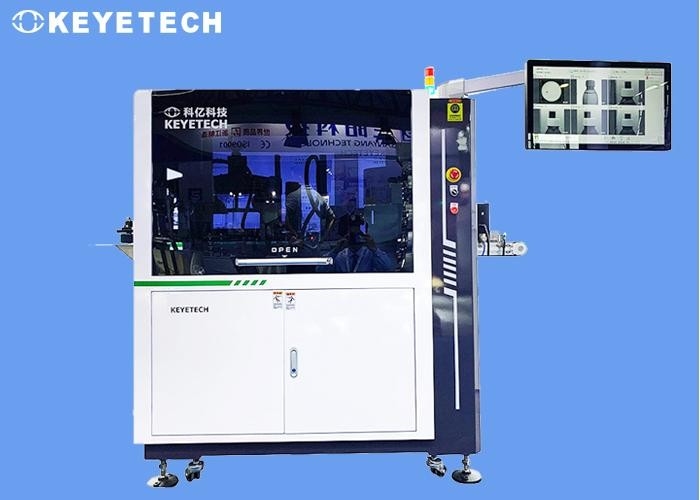

4)Save labor costs and enable high repetitive work:CCD visual inspection can work stably for a long time, it is difficult for human eyes to observe the same object for a long time, and machine vision can perform measurement, analysis and recognition tasks for a long time. And it can continue to work, with low requirements for the natural environment of the application, in addition to saving product costs, it also greatly improves productivity.

5)Improve company competitiveness and employee safety factor:Non-contact detection, which does not cause any damage to observers and observers, improves the reliability of the system. Machine vision technology guarantees the ultimate human-machine interaction technology, which ensures a better and safer workplace.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!