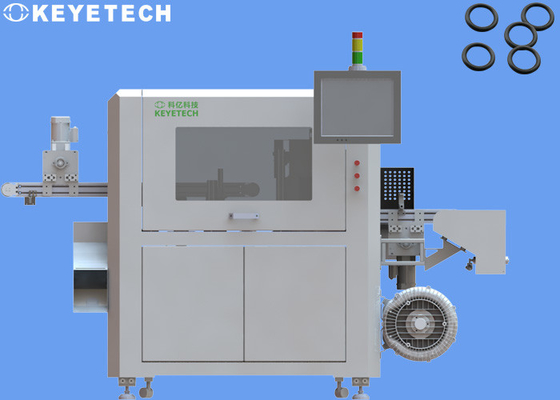

O-Ring Quality Inspection Machine Convey With Glass Vibrating Plate

The O-ring is a circular rubber ring with a circular cross-section. It is mainly used for mechanical parts to prevent leakage of liquid and gaseous media under static conditions. In some cases, it can also be used for axial reciprocation and low-speed rotation. Moving dynamic sealing element. According to different conditions, different materials can be selected to suit it. O-type rubber rings are usually selected as large-section O-rings as far as possible. In the case of the same clearance, O-type rubber rings are The volume squeezed into the gap should be less than the maximum allowable value for it to be squeezed into. For different kinds of fixed sealing or dynamic sealing applications, O-ring provides designers with an effective and economical sealing element.

System overviews

This system is used for O-ring detection, color recognition and product location acquisition. The system adopts imported high-resolution industrial color cameras, which can quickly acquire product images. Through image recognition, analysis and calculation, the product color is given, the product coordinates are given, and the output is Corresponding detection result signal is convenient for the equipment to deal with unqualified products.

Inspection principle

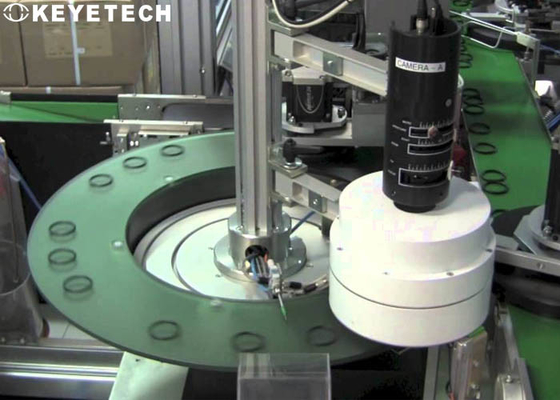

The O-ring color recognition and coordinate detection system developed by KEYE TECH Vision System Co., Ltd. based on machine vision image processing technology has the characteristics of high precision, high speed and multiple samples. The main modules of the system are: trigger module, image processing module. According to the user's needs, the sample moves to the detection position, triggers the camera and outputs the detection signal from the vision system in time, so as to complete the detection

test function. In order to meet the high-precision detection requirements, first of all, the position of the incoming product must be consistent, and the effect achieved is that the position is accurate and stable.

Main function of equipment

| Speed |

2pcs/sec |

| Accuracy |

>99% |

| Image capture |

Automatically complete the synchronization of the inspected product and the image obtained by the camera |

| Defect identification |

Automatically complete the color recognition coordinate position of the O-ring |

| Storage and Statistics |

Automatic storage of product images, historical query; automatic statistics (good products, defective products, total number, etc.) |

| Deep learning algorithm |

The system has self-learning function, and the learning process is easy to operate |

Technical features

- The operation interface is clear and clear, simple and easy to operate, and the detection can be automatically performed with a simple setting;

- The detection software and algorithm are completely independently developed, and the system is highly targeted;

- The detection template and detection range can be set flexibly;

- The local detection function can be selected to improve the detection speed;

- Professional light source design, clear and uniform imaging, to ensure the completion of measurement tasks;

- Support the measurement of various types of products, and have the functions of online automatic detection of products;

- Simple installation; compact result, easy to operate, maintain and expand;

- High reliability, stable operation, suitable for various field operating conditions.

- Based on PC platform, the system has strong scalability.

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!