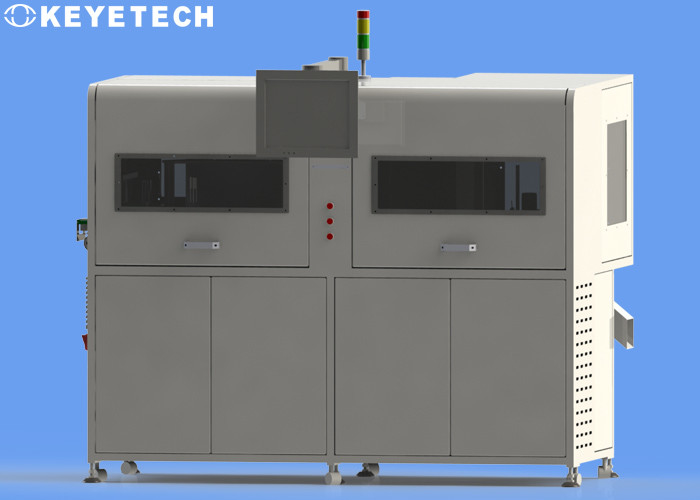

KEYE High Precision Automated Visual Quality Inspection Machine

Appearance inspection can usually be used for the following inspection contents: the following example, more than 95% of industries can use machine vision appearance inspection to replace manual labor:Detection of foreign matter adhering to food packaging;Detection of stains attached to cloth;Detect flaws on metal and resin parts;Detect defects (blemishes, burrs) that occur during resin and rubber molding;Check whether the lighting of the LED is missing defect detection, etc.Traditional appearance inspection relies on visual inspection. With the development of factory automation, vision systems are more and more widely used in the field.

Inspection principle

Can distinguish subtle foreign objects, flaws and defects: For the appearance inspection that had to rely on human eyes to judge in the past, with the advancement of vision system and vision system technology, the detection of subtle foreign objects, flaws and defects has also become possible. We have launched a variety of vision system products ranging from standard 310,000 pixels to 21 million pixels of high resolution. According to the needs of customers, we can provide customers with cost-effective vision system systems.

Equipment overview

-Online high speed detection, improve detection efficiency and accuracy, reduce human cost.

- High-pixel industrial camera accurate identification, the number of cameras is designed, accurate 0.1mm, speed can be customized according to the detection requirements.

- Compatible with multiple specifications, cost savings.

-Perform online detection and exclude for disabled fork defects:black spots, color difference, impurities, gaps, residues of material, overlaps, bubbles, air cavities, deformation, thickness, sizes, etc.

| Name |

Defect detection equipment |

Model |

Kvis |

| Software Algorithm |

Deep Learning |

Voltage |

Ac220/50Hz |

| Voltage |

2kw-4kw |

Air Pressure |

Mpa |

| Transfer Method |

Lossless Delivery |

Detection Status |

Online Real-Time Detection |

| Detection Method |

High-Speed Industrial Camera |

Number Of Camera |

1-6 set |

Features of system

Appearance inspection can find foreign objects, stains, flaws, defects, etc., and prevent the outflow of defective products, but visual inspection has accuracy limits. Full detection not only consumes labor and cost, but also leads to precision deviation and human error due to individual differences.

- AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training

- Dataization: Independent database, save multiple samples, analyze non-good products, and retain history

- Multi-orientation: 360 ° comprehensive inside and outside the samples

- High precision: detection accuracy can be high

- Modularization, can flexibly increase or decrease the detection function according to customer actual needs

- Easy to operate: It is easy to operate and easy to maintain

- Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment

In addition, subtle flaws and stains are difficult to detect. To maintain quality, magnification inspections must be carried out with the help of tools such as microscopes. When the number of points is small, the microscope inspection can be performed offline, but when the inspection of thousands of points is required, a huge amount of labor is required, resulting in a significant decrease in production efficiency. To balance quality and production efficiency, vision system technology is an indispensable and important link.

Machining process

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!