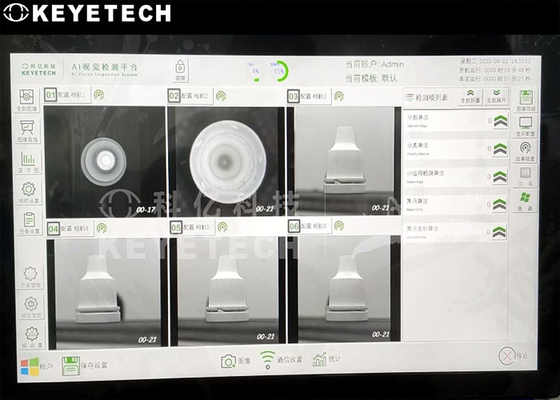

Dropper Cap Camera Visual Inspection Machine HMI Touch Screen Support

Company profile

Anhui Keye Information Technology Co., Ltd. is a national high-tech enterprise focusing on AI technology research and development and product implementation. It provides overall solutions such as AI visual imaging, algorithm computing power and automatic control for various sub-industries.

Relying on the Key Laboratory of Pattern Recognition of the University of Science and Technology of China, the company has established a high-end R&D team led by 7 doctors, integrating optics, mechanics, electricity, computing and software. Build a KVS-AI software and hardware platform, so that AI technology can be transformed into real productivity.

Application Background

- In the process of manual inspection, the inspection personnel have a large deviation in the implementation of the standard, and the management is difficult

- In the manual inspection process, there are subjective differences in the inspection standards of different inspectors, and the consistency is low.

- The process of manual inspection cannot be accurately recorded, and the traceability is low

- In the process of manual inspection, long-term work will lead to visual fatigue of inspectors, and false inspections and missed inspections are prone to occur

Inspection principle

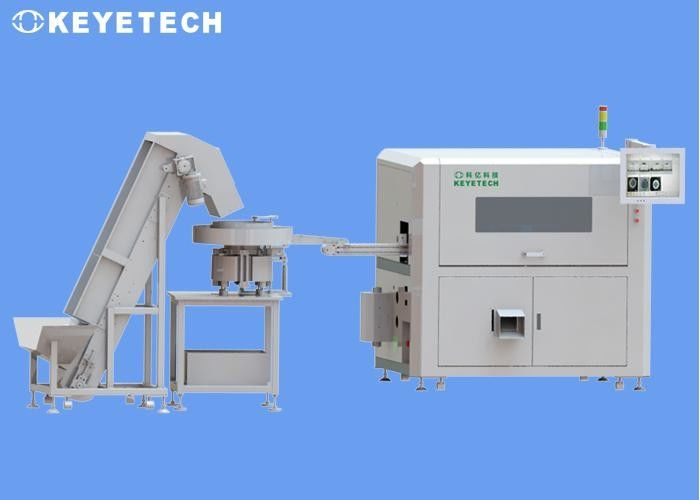

1) The machine vision inspection system is used to detect product quality on the production line, which is also the part that replaces the most labor;

2) Use machine vision inspection systems for high-precision inspection;

3) Utilize machine vision systems to process, analyze and understand images to identify targets and objects in different modes;

4) The method of machine vision inspection system can greatly improve production efficiency and automation.

System Features

1. High accuracy, artificial intelligence AI detection, the error is controlled within 0.5%;

2. High efficiency, 2 minutes to complete the test, one is equivalent to 3 manual workers;

3. Intelligent, three-dimensional, easy to operate, you can use it in 3 minutes;

4. Femto-visible, high-precision camera omni-directional detection 0.04mm recognition accuracy;

| power |

<200 W 220~230V |

| voltage range |

Single-phase alternating current 200~240V,50HZ |

| Environment temperature |

-10℃~+45℃(No icing) |

| Environment humidity |

Below 85% (no condensation) |

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!