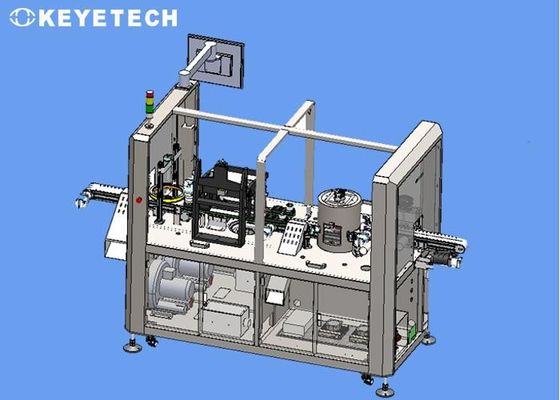

EBI Visual Inspection System Ensure Product Quality with Online NG Rejection

Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

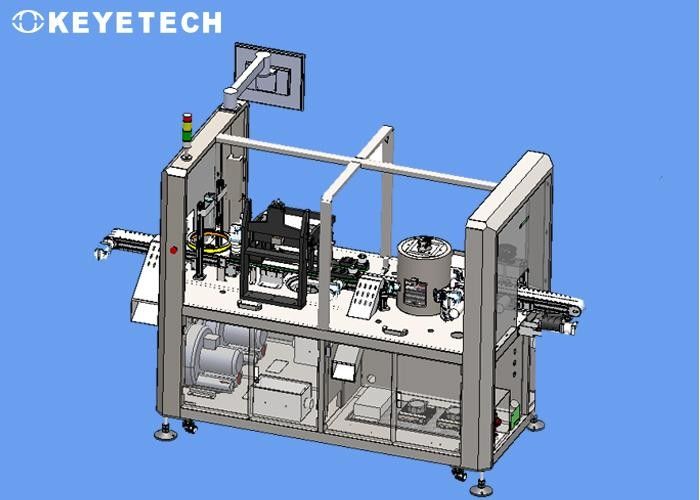

CCD visual inspection details

CCD visual inspection and positioning system uses image sensors to replace human eyes, 100% accurate detection of surface defects and defects, and statistics, classification and analysis of defect information, optimization of production process control, classification of products, and classification of qualified and unqualified products. Classify to improve customer trust and satisfaction. CCD machine vision system is a high-tech product used for industrial inspection and identification. The core problem of production is the selection of industrial computer system, which can collect high-definition images of processed products and directly transmit them to the GPIO interface of the machine.

Detection details

| Model |

Camera number |

Detection range |

Detection content |

Detection accuracy |

Detection speed |

|

KY-PB

|

1set |

Bottle mouth |

Black spots, stains, overlap, burrs, lack of material, etc. |

≥0.5mm |

100-200 pcs/min

|

| 1set |

Bottom of the bottle |

Black spots, stains,foreign material, etc. |

≥0.5mm |

| 4 set |

Upper area of the bottle |

Black spots, stains,missing, etc. |

≥0.5mm |

| 4set |

Lower area of the bottle |

Black spots, stains, etc. |

≥0.5mm |

| 1set |

Outer bottom of the bottle |

Black spots, stains |

≥0.5mm |

| Hole |

≥1mm |

Advantages of visual inspection

- High detection accuracy and fast detection efficiency:CCD visual inspection equipment uses machine control according to the system, with small error and high detection rate.

- Wide detection range to detect cosmetic defects and dimensional measurements:The multi-station inspection method can accurately measure the outline, specifications, appearance defects, product aspect ratio and other performance parameters of the product to be inspected at one time.

- Improve product quality and error rates:Vision inspection equipment is based on system control, which can distinguish good products from bad products through automatic inspection technology, and then automatically place them in different parts.

- Save labor costs and enable high repetitive work:CCD visual inspection can work stably for a long time, it is difficult for human eyes to observe the same object for a long time, and machine vision can perform measurement, analysis and recognition tasks for a long time. And it can continue to work, with low requirements for the natural environment of the application, in addition to saving product costs, it also greatly improves productivity.

- Improve company competitiveness and employee safety factor:Non-contact detection, which does not cause any damage to observers and observers, improves the reliability of the system. Machine vision technology guarantees the ultimate human-machine interaction technology, which ensures a better and safer workplace.

Cooperation Partners

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

** Our company have served many well-known enterprises such as Coca-Cola, P&G, Unilever, ALPLA, Shriji Polymer, Berry Global, Aptar, LAMIPAK, TPAC, PACT Group, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!