Product background

The bottle cap visual inspection system is used in beverages, medicines, cosmetics, beer and other industries to detect the size, defects, stains, and center pattern deviation of bottle caps. The system will acquire the images of online bottle caps in real time, judge whether they meet the requirements through image positioning and analysis, and output control signals. The maximum detection speed of the system can reach 2500 pieces/min.

The traditional manual inspection method has been difficult to meet the inspection needs of the bottle cap production process in the beverage, pharmaceutical and other industries. Quality control is the core competitiveness of modern manufacturing manufacturers. To ensure high-quality products, it is inseparable from modern intelligent testing equipment. The introduction of automated visual inspection machines for bottle caps is an essential choice for bottle cap production and inspection, and it is also a long-term way to win the market.

Inspection principle

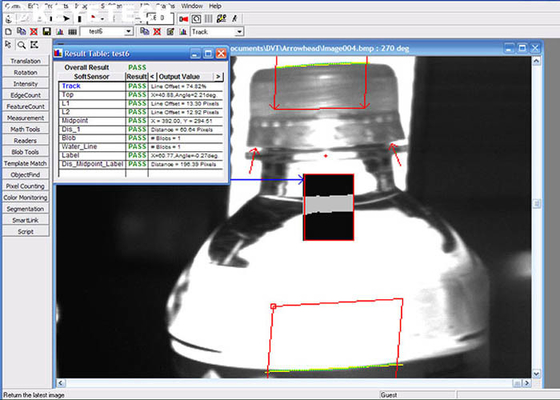

The bottle cap inspection machine adopts machine vision technology to measure, judge and analyze the detected object with the machine instead of the human eye. To a dedicated image processing system, according to pixel distribution, brightness, color and other information, converted into digital signals. The image system performs various operations on these signals, extracts the characteristics of the target, and then controls the action of the equipment on the spot according to the judgment result of the set standard, and the unqualified products are automatically rejected. In this way, the detection process can realize automatic feeding, automatic detection, automatic sorting, unloading, packing, packing and other system operations, and the detection work is more efficient and fast.

Equipment overviews

| Item |

| Closure caps inspection machine |

|

Main Material |

Stainless steel |

| Software Algorithm |

Deep Learning |

Voltage |

Ac220/50Hz |

| Voltage |

4kw |

Air Pressure |

0.5-0.8Mpa |

| Transfer Method |

Lossless Delivery |

Detection Status |

Online Real-Time Detection |

| Detection Method |

High-Speed Industrial Camera |

Number Of Camera |

Depending on the specific situation

|

Advantage of visual inspection

1)High detection accuracy and fast detection efficiency:CCD visual inspection equipment uses machine control according to the system, with small error and high detection rate.

2)Wide detection range to detect cosmetic defects and dimensional measurements:The multi-station inspection method can accurately measure the outline, specifications, appearance defects, product aspect ratio and other performance parameters of the product to be inspected at one time.

3)Improve product quality and error rates:Vision inspection equipment is based on system control, which can distinguish good products from bad products through automatic inspection technology, and then automatically place them in different parts.

4)Save labor costs and enable high repetitive work:CCD visual inspection can work stably for a long time, it is difficult for human eyes to observe the same object for a long time, and machine vision can perform measurement, analysis and recognition tasks for a long time. And it can continue to work, with low requirements for the natural environment of the application, in addition to saving product costs, it also greatly improves productivity.

5)Improve company competitiveness and employee safety factor:Non-contact detection, which does not cause any damage to observers and observers, improves the reliability of the system. Machine vision technology guarantees the ultimate human-machine interaction technology, which ensures a better and safer workplace.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!