Due to the continuous update and development of modern electronic products, many people pay great attention to the protection of eyes. Problems such as visual fatigue, eye inflammation, and myopia have corresponding eye drops that can be treated and relieved. Eye drops caps also have a certain degree of particularity. At the same time, because of the capacity characteristics of the eye drops itself (to ensure effective medicinal properties, the eye drops bottles are generally not too large), this leads to smaller caps, which are in mass production. In the process, manual detection of visual fatigue will lead to low detection efficiency, and because it is a product used in the eye, it must be produced in strict accordance with the production standards of the State Drug Administration, so the appearance of the eye drop bottle cap is also particularly important. , Time is productivity. KEYE Technology has many years of market experience in bottle cap inspection. It can tailor a customized bottle cap inspection system for enterprises, which can greatly improve inspection efficiency and save productivity.

Summary

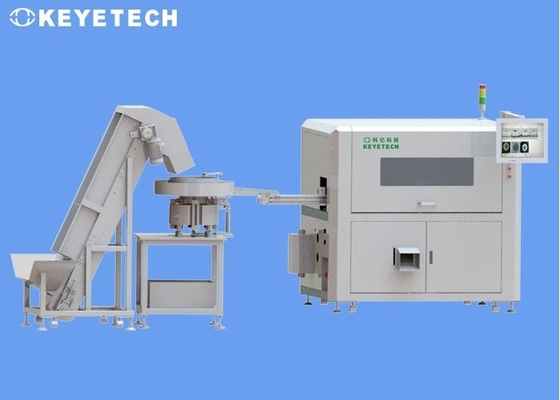

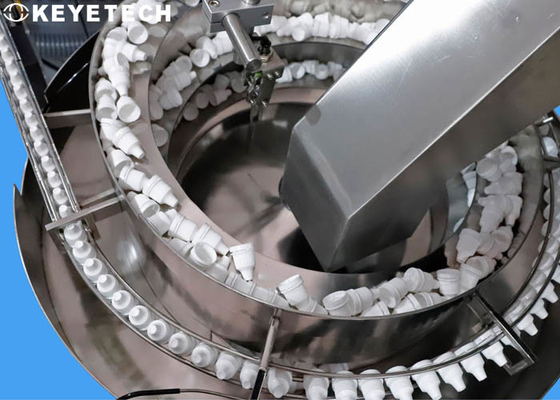

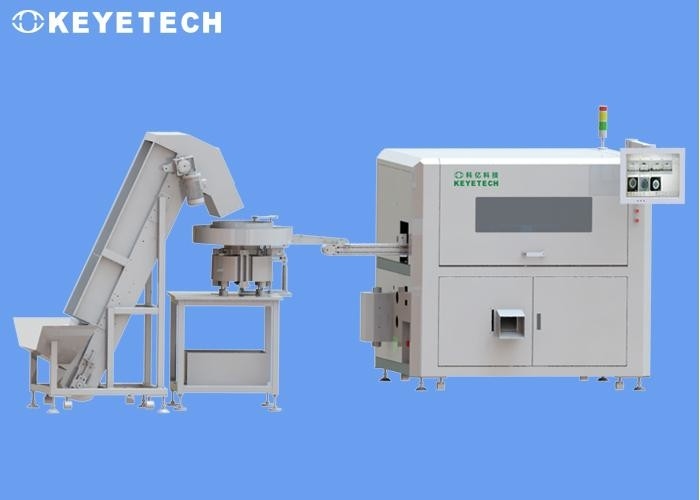

The whole system is a centrifugal turntable sorting machine and visual inspection system software, defective product rejection and counting device, the cover is downwards through the turntable sorting machine lid into a row into the photographing area of the visual inspection equipment, the normal inspection speed is 120-150 pieces/ Minutes, the equipment can operate 7*24 hours a day, which greatly improves production efficiency.

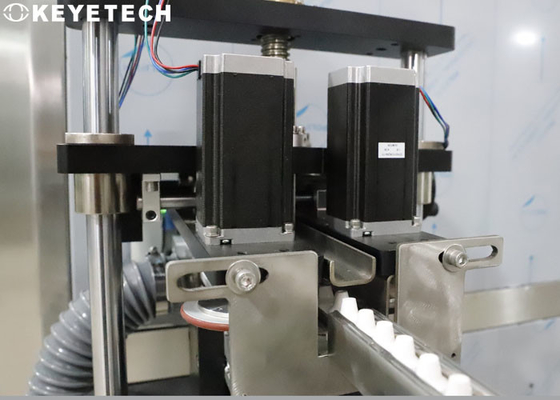

The whole system adopts 304 stainless steel shell, the air transmission track is sealed with acrylic PC board, and 8 sets of high-pixel industrial cameras are used to comprehensively detect defects in the visual appearance of the lid. After the system collects sample images, the image processing software is used After comparing and analyzing with the standardized model, the good product and the defective product are judged, and the defective product is automatically eliminated online. After the finished product is tested, the counting function can be realized, and the counting accuracy rate is 100%. The software will open the sample comparison standard, and the production personnel on the customer site can control the comparison accuracy and choose the accuracy standard most suitable for their own production conditions, thereby controlling the defect rate.

Inspection Details

1,This inspection requirement determines the number of cameras to be used and the corresponding inspection content according to the needs of the end customer. The following table is for reference.

2,Inspection Standard

| Model |

Number of camera

|

Inspection scope

|

Inspection content

|

Accuracy

|

Capacity |

| KVIS-C-SC08 |

2 sets |

Top area

|

0.2mm< black spot |

99% |

120-150Pcs/min

|

|

0.5mm<Flash / not smooth

|

99% |

| 0.3mm<oily(with obviously color difference) |

99% |

|

4 sets

|

Side area

|

0.2mm< black spot |

99% |

| 0.5mm< oily(with obviously color difference) |

99% |

|

Ring area

|

0.5mm<Injection incomplete, broken (no touching)

|

99% |

| 1 set |

Bottom area

|

0.2mm< black spot |

99% |

|

0.5mm<Injection incomplete, flash

|

99% |

|

0.3mm<Oily(with obviously color difference)

|

99% |

|

1 Set

|

Injection point

|

0.3mm<Injection point not smooth

|

99% |

3,After the finished product is tested, it can realize double-channel sub-box counting, and the counting accuracy rate is 100%.

4,The testing equipment needs to be regularly maintained and cleaned during use (such as conveyor belt cleaning, camera cleaning, etc.). The testing equipment itself will not cause secondary pollution sources (such as debris, fine foam, etc.) to the tested samples.

5,Note: In actual production, a large area of anti-theft ring lacks glue as shown in the figure below. This kind of product cannot stand upright and seriously affects the stable operation of the material handling equipment. Abnormal problems such as material jam will occur, and manual intervention is required to handle this type of cover. The equipment downtime caused by the problem.

6,Since the vision camera cannot freely change the angle of observation like a human, there will be blind area. The following is the description of the detection blind spots:

Concave surface of bottle cap: The concave surface is detected as a camera with the lens on the inner side of the ring to take pictures vertically. Although the lens on the inner side of the ring expands the inner side of the concave surface, the captured image will shrink to a certain extent, causing the detection dead angle to be mainly concentrated in the two threads. Between black spots.

Anti-theft ring part: If the anti-theft ring is broken, if you need to manually squeeze it to see the obvious break of the anti-theft ring, such situation detection equipment cannot detect it.

7,Reference pic

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!