AI Algorithm Empty Bottle Inspection Machines for Food Beverage Manufacturer

Test Principle

Product safety has top priority in the production of pharmaceutical and medical products. Pharmaceutical and medical packaging with surface defects, a wrong label or code, contaminations or a leaking closure severely endangers the health of patients. This is why vision inspection has become inevitable since it guarantees the quality of 100% of produced parts.

Reducing recall risks and response time play major roles as well. Moreover, an increase in productivity and accuracy should not be disregarded. Thus, it is especially important in the pharma and medical industry to have a tight control over the whole production process. This becomes possible by a huge range of data collected by a vision system. KEYE vision systems convert these data automatically into meaningful statistics, diagrams, and reports.

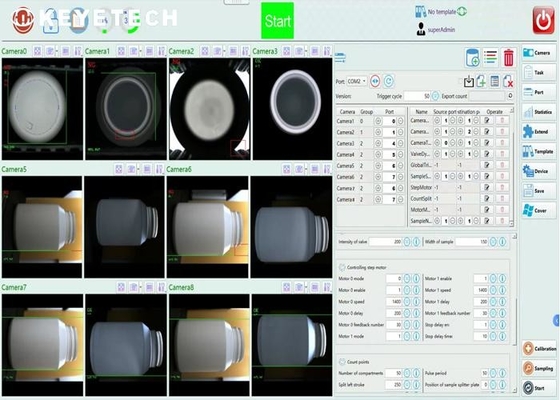

Visual system features

1)Visual Analytics--Computer Vision is a scientific field that allows computers to gain a high-level of understanding from digital images, videos, and live streams. This is done with the ultimate result of enabling computers and machines to understand and react to real world visual data similarly to how a human would.

2)Quality Control--From a manufacturing perspective, computer vision uses automated visual inspection capabilities to examine every procedure in the production process, detecting the assembly of different items, locating defective parts, and identifying yield.

3)Security--In terms of security, Matroids’s computer vision software uses AI based visual inspection tools to monitor thousands of live streams for suspicious actions, unusual objects, or unwanted activities.

4)And More--Computers can be taught through computer vision software (and Matroid) to detect anything from wildfires to defects on printed circuit boards to hand washing procedures. PPE, agricultural inspections, structural integrity, and crowd safety are just a few more topics that computer vision can tackle.

System Overviews

| System operating parameters |

| System size |

See design drawings for details |

Voltage and current |

220V 20A 50HZ |

| Equipment Power |

5.0-6.0kw |

Compressed Air |

0.5~0.8Mpaclean And Oil-Free |

| Ambient Temperature |

-20℃ ~ 60℃ |

Environment Humidity |

Below 50% Relative Humidity |

Testing standards

| Model |

Camera |

Scope Of Test |

Test Content |

Detection Accuracy |

Accuracy |

Detection Speed |

|

Kvis-Sc10

|

1set |

Bottle Mouth Area |

Black Spots, Stains,

Impurities (Different Colors)

|

≥0.2mm |

99% |

120/min |

| Flash, Lack Of Material |

≥1.0mm |

99% |

| 4 Sets |

The Upper Area Of The Bottle Body (Including The Outside Of The Bottle Mouth) |

Black Spots, Stains,

Impurities (Different Colors)

|

≥0.2mm |

99% |

| Bubble |

≥1.0mm |

99% |

| 4 Sets |

Lower Area Of Bottle |

Black Spots, Stains,

Impurities (Different Colors)

|

≥0.2mm |

99% |

| Bubble |

≥1.0mm |

99% |

| 1 Set |

Outer Bottom Of Bottle |

Black Spots, Stains, |

≥0.2mm |

99% |

| Impurities (Different Colors) |

≥1.5mm |

99% |

|

Hole

(Penetration, No Adhesion In The Hole)

|

≥1.0mm |

99% |

Company profile

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

** Our company have served many well-known enterprises such as Coca-Cola, P&G,Unilever,ALPLA,C'estbon, Nongfu Spring, etc., and has won praise from many users.

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!