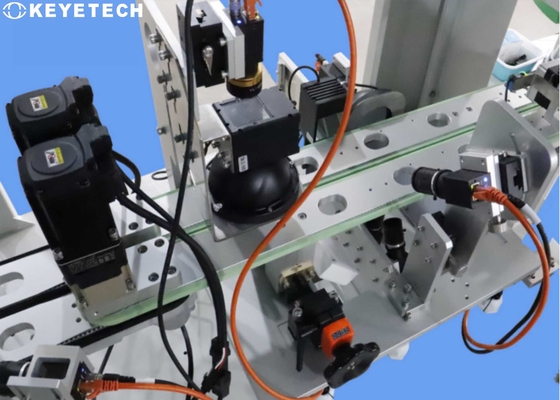

Euro Cap Vision Sorting Machine Appearance Defect Detection Equipment

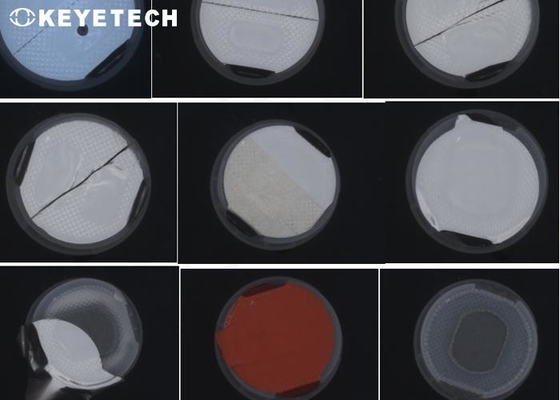

Inspection Principle

(1)The high-pixel sample image captured by the industrial camera is transferred to the image processing software. After the system analyzes and processes, it judges good and defective products, and controls the corresponding pneumatic components to eliminate the defective products, and finally collects qualified products.

(2)Transmitted the shooting high-pixel sample image to image processing software by industrial camera, detecting and

determining a good product and defective product via AI manually intelligent algorithm.

(3)AI artificial intelligence algorithm to determine the pros and cons of products, to achieve automated production lines

Equipment Overviwes

| Item |

Cap sorting machine

|

Main Material |

SS 304/Carbon steel |

| Software Algorithm |

Deep Learning |

Weight |

300-500kg |

| Voltage |

5-7kw |

Air Pressure |

0.4-0.6Mpa |

| Transfer Method |

Lossless Delivery |

Detection Status |

Online Real-Time Detection |

| Detection Method |

High-Speed Industrial Camera |

Number Of Camera |

Depending on the specific situation |

Software Function

Ø Enabling and disabling the system detection function

Ø Detection index parameters and accuracy adjustment

Ø Template sampling and saving, storage and retrieval of sample information

Ø Camera screen calibration function

Ø Real time production information display of the system (qualification rate, total output, speed, etc.), browsing of historical production information, export and storage functions

Ø Manage permissions based on login account (example, disabling parameter adjustment for general operation users)

Ø Operation and adjustment of the mechanical part of the system (If the transmission device is turned on, adjust the alarm signal)

Our Advantages

- AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training.

- Dataization: Independent database, save multiple samples, analyze non-good products, and retain history.

- Multi-orientation: 360 ° comprehensive inside and outside the bottle without dead corners for medical packaging bottle caps, bottle mouths, bottle bottoms.

- High precision: detection accuracy can reach 99.5%.

- Modularization, can flexibly increase or decrease the detection function according to customer actual needs.

- Easy to operate: It is easy to operate and easy to maintain.

- Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment.

Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!