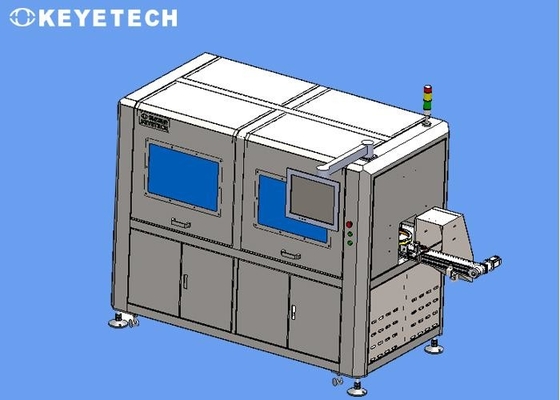

PP Multifunctional Rebate Cup Lid Testing Equipment

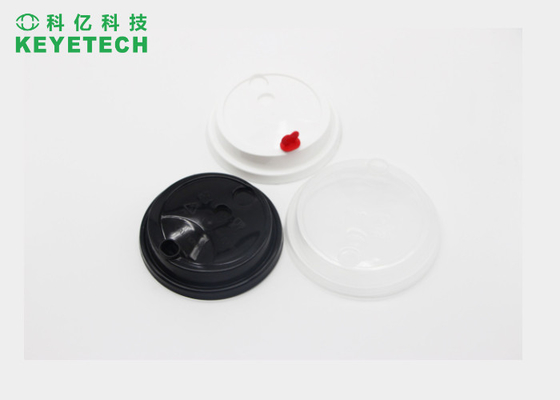

The PP multifunctional rebate cup lid inspection equipment is an equipment for all-round detection of defects in the PP multifunctional rebate cup lid in the production process. The rebate cup lids are mostly those equipped with high-end milk tea shops. During the production process of the cup lids, the thickness and airtightness of the cup lids should be considered. After multiple production processes, the cup lids should be closed Defects caused by mass production may be left, and manual visual inspection may be incomplete due to various objective factors, which will affect the overall quality of the product, so most manufacturers will introduce more accurate visual inspection equipment, better Cooperate with the operation of the overall production line.

Detection principle

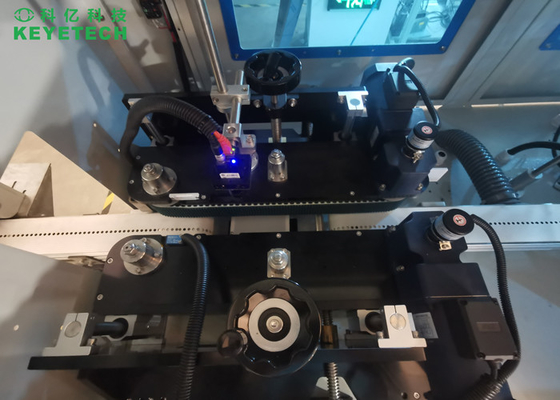

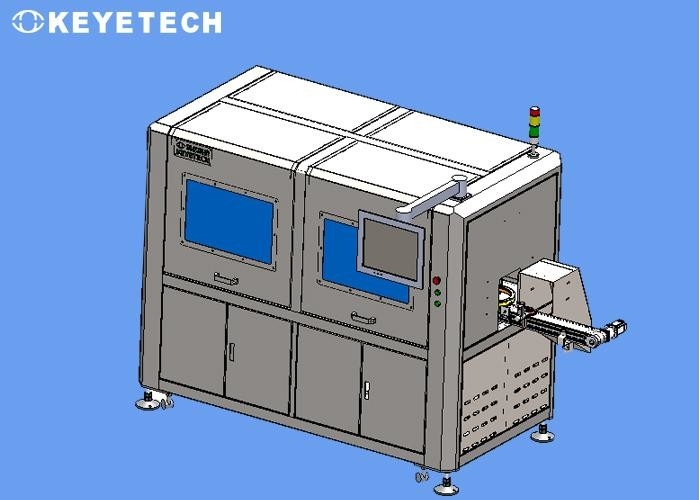

The PP multi-functional rebate cup lid detection equipment is connected to the front-end automation mechanism (which can be directly connected to conveying lines, waterfall-type cap arranging machines, centrifugal turntables, etc., depending on the implementation method to be determined on the production site), and the PP multi-functional The rebate cup cover is stably and orderly transmitted to a specific inspection station, and then the high-pixel sample image captured by the industrial camera is transmitted to the image processing software, and the AI artificial intelligence algorithm detects and determines the good and bad products, and controls the corresponding. Pneumatic components remove defective products, and finally output qualified products. The conveyor platform at the back end of the testing machine can be connected to the automatic packaging mechanism.

Product configuration

●High pixel industrial camera

●High resolution industrial lens

●High-brightness strobe light source

●Artificial intelligence (Al) algorithm

●High-performance GPU computing processing platform

●High-resolution industrial touch screen

Equipment overview:

➢ Online high-speed detection, improve detection efficiency and accuracy, and reduce labor costs.

➢ Accurate identification of high-pixel industrial cameras, the number of cameras is designed on demand, the accuracy is 0.1mm, and the speed is 300 pieces/min (can be customized according to testing needs).

➢ Compatible with testing products of multiple specifications, saving costs.

➢ Detect and remove defects such as black spots, color difference, impurities, gaps, residual material, flash, bubbles, voids, deformation, uneven thickness and size of PP multi-functional rebate cup lids online.

| Name |

PP multifunctional rebate cup lid testing equipment

|

Model |

Kvis-Sc02 |

| Software Algorithm |

Deep Learning |

Voltage |

Ac220/50Hz |

| Voltage |

200w |

Air Pressure |

Mpa |

| Transfer Method |

Lossless Delivery |

Detection Status |

Online Real-Time Detection |

| Detection Method |

High-Speed Industrial Camera |

Number Of Camera |

Depending on the specific situation |

Product advantages

- AI algorithm: high stability, can adapt to the disturbance of the environment and background; after training, it can automatically identify different defect samples.

- Dataization: independent database, save a variety of samples, analyze defective products, and keep historical records.

- Visualization: Real-time display of sample images, running status, real-time statistical inspection results and defective product defect classification information.

- High precision: The detection accuracy rate can reach 99.5%.

- Easy to operate: The equipment is easy to operate and easy to maintain.

- Safety: Made of medical-grade materials, it fully conforms to the production environment of medical supplies.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!