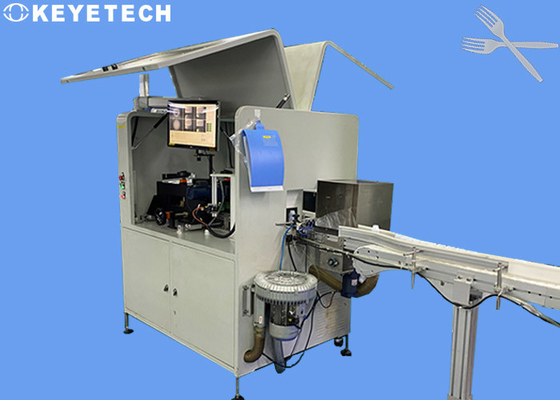

Disposable fork defect detection equipment is a full-scale detection of defects in the production process. Disposal fork is a very

| Name |

Disposable fork defect detection equipment |

Model |

Kvis-Sc02 |

| Software Algorithm |

Deep Learning |

Voltage |

Ac220/50Hz |

| Voltage |

200w |

Air Pressure |

Mpa |

| Transfer Method |

Lossless Delivery |

Detection Status |

Online Real-Time Detection |

| Detection Method |

High-Speed Industrial Camera |

Number Of Camera |

1

|

wide dishware in the bubble surface, fast food and other industries, and people choose to use disposable tableware because the use is convenient and fast, and time saving. However, during the production process, due to the disadvantage of automation production, it is impossible to find problems in the production process, and through manual testing will cost a lot of time, human, material. Therefore, many manufacturers have professional equipment to fully test products.

Detection principle

Disposable fork defect detection equipment through the docking front automation mechanism (can directly contact the conveyor line, the waterfall cover machine, the centrifugal turntable and multiple typing mechanisms, specifically based on the production site to determine),the disposable forks are stably transmitted to a specific detection station.Then transmitted the shooting high-pixel sample image to image processing software by industrial camera, detecting and determining a good product and defective product via AI manually intelligent algorithm, and controlling the corresponding pneumatic components to remove the defective product, and finally get the qualified product. The detecting machine rear end conveying platform can interface the automated packaging mechanism.

Product configuration

●High pixel industrial camera

● High resolution industrial lens

● High brightness frequency flash source

● Artificial intelligence (AL) algorithm

● High performance GPU calculation platform

● High resolution industrial touch screen

Equipment overview

-Online high speed detection, improve detection efficiency and accuracy, reduce human cost.

- High-pixel industrial camera accurate identification, the number of cameras is designed, accurate 0.1mm, speed 300 / min (can be customized according to the detection requirements).

- Compatible with multiple specifications, cost savings.

-Perform online detection and exclude for disabled fork defects:black spots, color difference, impurities, gaps, residues of material, overlaps, bubbles, air cavities, deformation, thickness, sizes, etc.

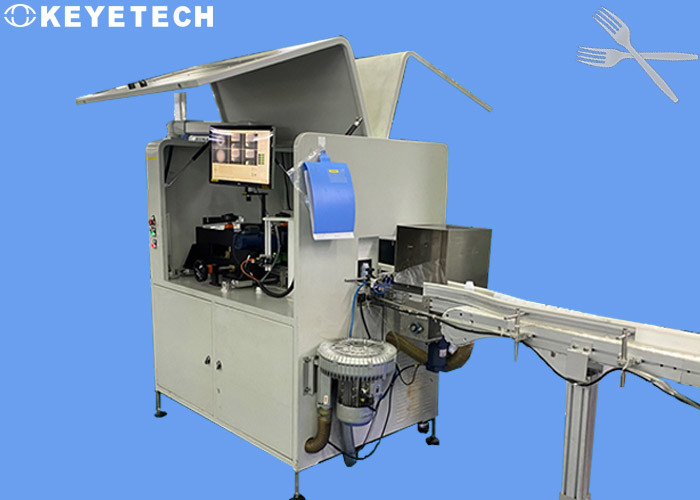

Product advantages

- AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training.

- Dataization: Independent database, save multiple samples, analyze non-good products, and retain history.

- Multi-orientation: 360 ° in the inside and outside of the disposable fork, 360 ° in the outside without dead angle detection.

- Visualization: Real-time display sample image, operating state, real-time statistical test results and defects classification information.

- High precision: detection accuracy can reach 99.5%.

- Modularization, can flexibly increase or decrease the detection function according to customer actual needs.

- Easy to operate: It is easy to operate and easy to maintain.

- Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!