| System Parameters |

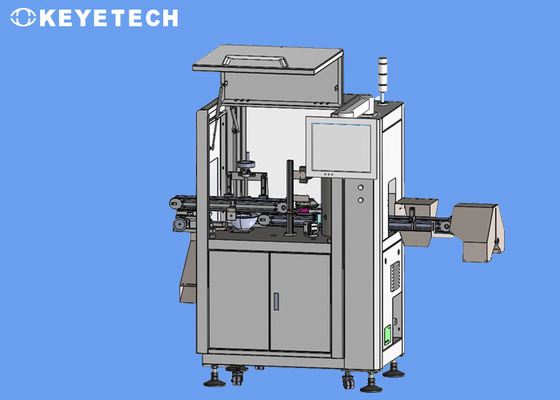

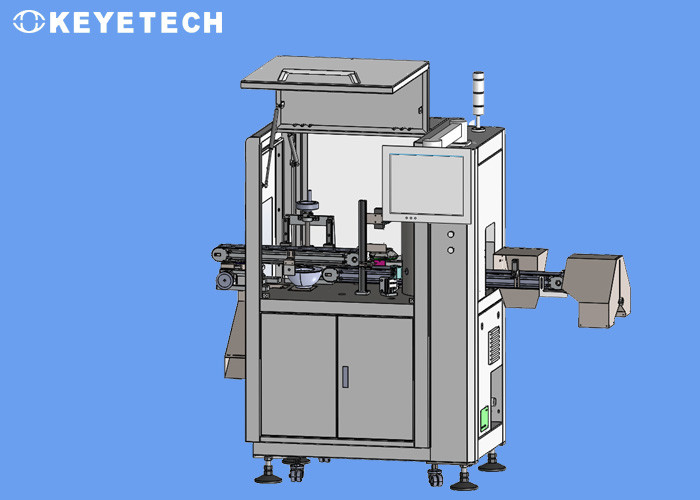

| Dimension |

Reference The Drawing |

Voltage |

220V 20A 50Hz |

| Power |

5.0-6.0kw |

Air |

Clean Air Without Oil |

| Temperature |

-20℃ ~ 60℃ |

Humidity |

Less Than 50% |

Ai Inspection System For The Multi-Specification Flat Top Cover

1. Inspection Object

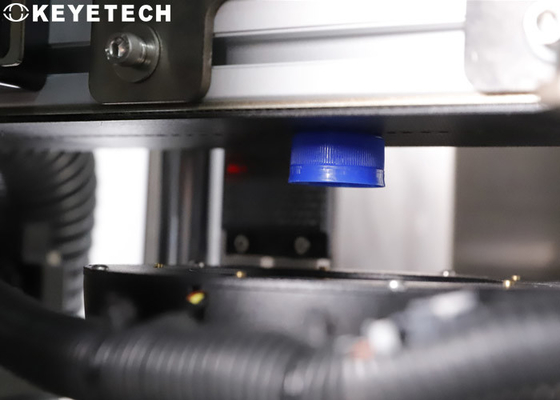

Flat-top caps are the most used accessory products for bottle products, and the demand in the market is increasing day by day. Flat-top caps with multiple specifications, plastic materials, and various colors are divided into various specifications. Please refer to the actual sample for details.

In order to realize the compatible detection of the above-mentioned products of different specifications, it needs to involve the front-end and back-end automation mechanisms, the adjustment of the interface position of the detection machine and the focal length of the camera, and the switching of the detection software. Do analysis.

2. Inspection Principle

By docking the front-end automation mechanism (the connection method needs to be docked in advance), the multi-specification flat top cover is stably and orderly transferred to a specific inspection station with the cover facing down, and then the captured high-pixel sample image is captured by an industrial camera. It is transmitted to the image processing software. After the system analysis, it determines the good and bad products, and controls the corresponding pneumatic components to remove the bad products. Finally, the qualified products are output.

The software will open the sample comparison standard, and the production personnel at the customer site can control the comparison accuracy and select the most suitable accuracy standard for their own production conditions, thereby controlling the defect rate.

3. Inspection Details

Our design plan adopts 11 sets of high-pixel industrial cameras and high-performance stroboscopic light sources, and conducts a full range of visual inspections for the appearance defects of multi-specification flat-top cover products. The inspection speed is 200 pieces/minute, and the equipment can achieve 7* It operates 24 hours a day, and the unqualified products can be automatically rejected online.

The whole set of testing equipment includes mechanical parts, visual electronic hardware and testing system software. The entrance and exit of the testing machine can be integrated with the automation mechanism (see the design drawings for the specific connection method), and can be connected with upstream and downstream production according to the specific production needs of customers on site equipment.

1, inspection standard

2, Black spots, stains, hair, foreign objects, impurities (different colors), and macula will be analyzed and processed according to the black spot detection index. If the sample has transparent oil stains or light-colored black spots, and the gray value contrast difference is low (below 40), the detection effect cannot be achieved.

In the actual inspection, due to the influence of the critical fluctuation state of the data of some inspection items, there will be a certain probability of false inspection of the product, which can be adjusted through the parameter setting of the system software to achieve the actual effect.

2. Camera Instructions

- Cup lid front detection: Through the automatic mechanism, a single product can enter the detection station in a stable and orderly manner. A set of industrial cameras is arranged above the product, used with the visual front light source, and the image is collected and processed systematically.

- Ø Detection of the outer side of the cup lid: Considering the structural characteristics of the cup lid, 4 sets of industrial cameras are arranged in a circular shape on the outer side of the product, and used in conjunction with the visual light source, the images do not interfere with each other, and the images are processed systematically after they are collected.

- Ø Cup lid concave inspection: It is transmitted to the concave inspection station through the glass turntable mechanism, and a set of industrial cameras is arranged under the product, which is used in conjunction with the visual light source to collect images for system processing.

- Ø Detection of the front (transparency) of the cup cover: It is transmitted to the front (transparency) detection station through the glass turntable mechanism, and a set of industrial cameras is arranged above the product, which is used in conjunction with the visual light source to collect images for system processing.

- Ø Detection of the outer side (transparency) of the cup cover: It is transmitted to the outer side (transparency) inspection station through the glass turntable mechanism, and 4 sets of industrial cameras are arranged in a circular shape on the outer side, which is used with the visual light source, and the system is processed after collecting the image. .

3. The inspection equipment needs to be regularly maintained and cleaned during use (such as conveyor belt cleaning, glass plate cleaning, camera cleaning, etc.), and the counting function can be realized after the finished product is inspected.

4, About the system

(1)Mechanical part:

The mechanical part is the core component of the system, carrying all the transmission devices and electronic hardware (industrial cameras, light sources, industrial computers, touch screens, electrical boxes, etc.).

The glass turntable mechanism in the equipment can open the imaging angle of the concave surface of the product, so that the industrial camera can effectively collect images for analysis and processing.

(2)Hardware part

The hardware part includes camera, lens, light source, high-speed air valve, computer, touch screen and other electrical devices. For details, please refer to the equipment configuration details.

The overall logic control of the system is realized by a high-speed FPGA chip, and the specific functions include:

Ø Trigger the camera to take pictures

Ø Trigger light source strobe

Ø Trigger pneumatic parts to reject waste

Ø Control movement speed

Ø Emergency handling in case of similar system jam

Ø Trigger the alarm light signal

Software Part

The software is the master control platform of the equipment, and the specific functions are as follows:

Ø Enable and disable the system detection function

Ø Detecting index parameters and adjusting the accuracy.

Ø Template sampling and storage, sample detection information storage and recall.

Ø Camera image calibration function

Ø System real-time production information (qualified rate, total output, speed, etc.) display, historical production information browsing, export and storage functions.

Ø Manage permissions according to the login account

(For example, the general operation user disables the parameter adjustment permission)

Ø Operation and adjustment of the mechanical part of the system

(such as conveyor opening, pneumatic control, alarm signal adjustment)

Ø Other functions

5, image capture

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!