Rubber Components Quality Detection Machine with High Speed Industrial Camera

Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

Inspection Standards

| Name |

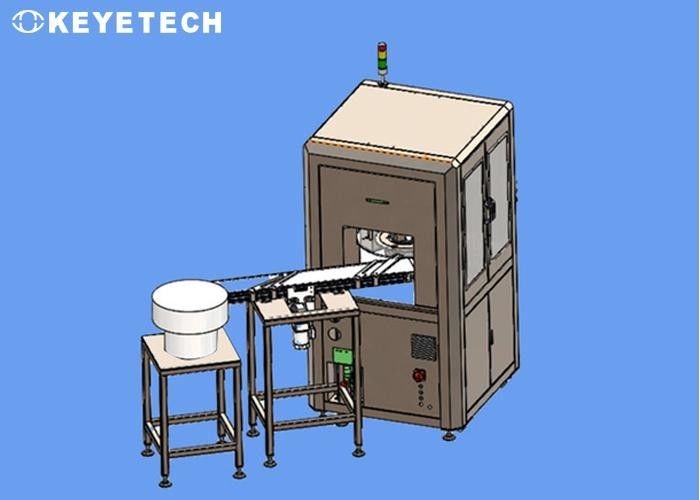

Glass disc type hardware quality detection machine |

Model |

Kvis-O-Cc03 |

| Rejection Device |

High-Speed Automatic Rejection |

Voltage |

Ac220/50Hz |

| Power |

2Kw |

Air Pressure |

0.4Mpa |

| Conveyor Way |

Vibrating Plate Feeding, Non-Destructive Conveying |

Detection Status |

Online Real-Time Detection

|

| Detection Way |

High Speed Industrial Camera |

Cameras Group |

Three Group |

| Software Algorithm |

Deep Learning

|

Size |

L1050mm*W1000mm*h 2100mm

|

|

Detection content (lathe parts as an example)

|

Deformation, aperture, hole spacing, breakage, missing edge, poor height and width, etc. |

Machine Overview

Hardware refers to tools obtained by processing and casting with metals such as gold, silver, copper, iron, and tin, which are used to fix things, process things, and decorate.

Product quality is related to many factors, both the design and the use of raw materials play an important role. But for hardware accessories, its quality also has an importance that cannot be ignored. Simply put, although hardware accessories are supporting roles, they determine whether they can ensure the quality and service life of the "protagonist".

The glass disc type hardware quality detection machine produced by our company can detect the quality of large and small products that can be placed stably in mass production, so as to ensure that each hardware piece can play a role and meet customer needs.

2. Using the principle of visual detection of visible objects, industrial cameras are used to convert the detected target into an image signal, and according to the pixel distribution, brightness, color and other information, it is converted into a digital signal. The image processing system performs various operations on these signals to extract the characteristics of the target, such as area, quantity, position, length, size,etc., by analyzing the image of the sample to obtain various parameters and standard products for real-time AI analysis, reject unqualified samples through compressed air, and automatically count qualified samples, to improve production efficiency.

3. Equipment function

Multiple cameras carry out 360-degree detection with no blind spots in all aspects of the product, and reject defective products according to the set standards.

·Real-time display of sample images and running status, real-time statistics of detection results and classification information of defective products.

The detection function and accuracy can be flexibly changed according to the needs of the scene, and 99.9% of the specified defects can be detected.

Save the characteristics of each sample to the model database, can switch the sample detection with one-click loading.

Statistical historical production records, multi-level authority user settings, one-key backup and restore system data.

The detection function is highly modular, and modules can be flexibly added or removed according to requirements.

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!