Product background

The function of the gear is to transmit the rotation of one shaft to another shaft, and it can also realize actions such as deceleration, acceleration, direction change and reversal. A gear is a mechanical element that continuously meshes with gears on the rim to transmit motion and power. The application of gears in transmission appeared very early. The principle of the generating gear cutting method and the special machine tools and tools that use this principle to cut teeth have appeared one after another. With the development of production, the stability of gear operation has been paid attention to.

As a universal mechanical part, the precision of gear has an important influence on the performance of mechanical products. Improving gear detection technology is the guarantee for improving the quality of gear products. Due to the characteristics of gear shape, there are many detection items, complex measurement process, and expensive measurement equipment. Machine vision inspection is a non-contact non-destructive inspection, which has great advantages compared with traditional inspection methods.

Inspection principle

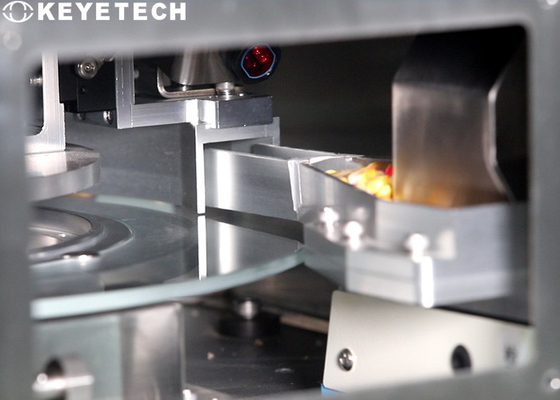

When the product is imaged on the background plate, it is processed by a special light source to obtain a clear image, and then analyzed by the image processing pattern recognition algorithm to obtain the result. The gear machine vision inspection system is mainly supported by industrial cameras, industrial lenses, and vision processing software. First, a CCD industrial camera connected to a computer is used to complete the image acquisition task, and the captured target is converted into an image signal.

Using the principle of visual detection of visible objects, industrial cameras are used to convert the detected target into an image signal, and according to the pixel distribution, brightness, color and other information, it is converted into a digital signal. The image processing system performs various operations on these signals to extract the characteristics of the target, such as area, quantity, position, length, size,etc., by analyzing the image of the sample to obtain various parameters and standard products for real-time AI analysis, reject unqualified samples through compressed air, and automatically count qualified samples, to improve production efficiency.

Equipment details&configurations

1)Multiple cameras carry out 360-degree detection with no blind spots in all aspects of the product, and reject defective products according to the set standards.

2)Real-time display of sample images and running status, real-time statistics of detection results and classification information of defective products.

3)The detection function and accuracy can be flexibly changed according to the needs of the scene, and 99.9% of the specified defects can be detected.

4)Save the characteristics of each sample to the model database, can switch the sample detection with one-click loading.

5)Statistical historical production records, multi-level authority user settings, one-key backup and restore system data.

| Name |

Gear Inspection machine |

Size |

900*800*1850mm |

| Computer |

Industrial PC |

Monitor |

19 inch |

| Industrial camera |

2 set |

Industrial lens |

2 set |

| Glass turntable |

1 pcs |

Samples |

0.6-30mm(diameter) |

| Feeding equipment |

vibration plate, direct vibration, controller |

Speed |

200-400/min |

Our advantages

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!