In Molded Labeling High Speed Bottle Vision Inspection Systems for IML Products

Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

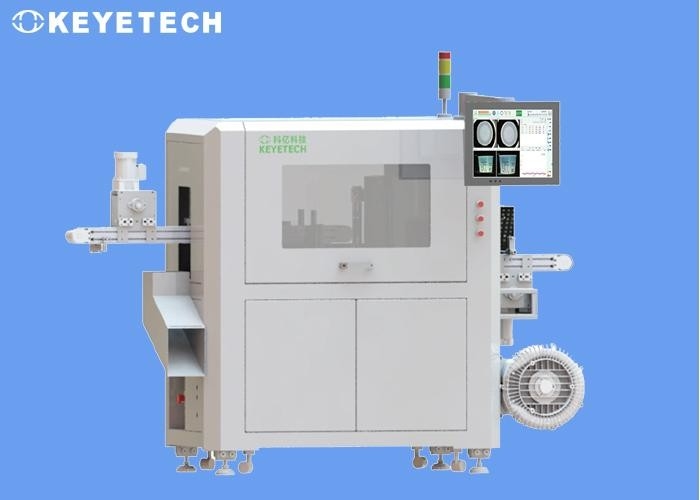

The detecting equipment is shown in the figure below (reference):

| System operating parameters |

| Dimensions |

See the design drawings

for details

|

Power and frequency |

220V 20A 50HZ |

| Total power |

5.0~6.0 kw |

Air pressure |

0.5~0.8MPa Purify and oil-free |

| Working temperature |

-20℃ ~ 60℃ |

Working humidity |

Below 50% relative humidity |

The detecting standards are as follows:

| Detection content and accuracy |

Detection precision |

Speed |

| Black spots, stains (different colors)≥0.2mm |

99% |

120pcs/min |

| Notches, overlap≥0.5mm |

99% |

| Black spots, stains (different colors)≥0.3mm |

99% |

| Black spots, stains (different colors)≥0.2mm |

99% |

| No printed content area |

| Label misalignment, labeling, damage≥0.5mm |

99% |

| Black spots, stains (different colors)≥0.2mm |

99% |

Inspection principle

Daily chemical products have penetrated into all aspects of people’s lives. When people choose daily chemical products, they will choose their habitual product brands according to their habits. There are more and more cosmetics and detergent manufacturers in China who choose in-mold labelled plastic bottles to package their own products. In-mold labeling technology will be more and more widely used in cosmetics, detergents, daily chemical industries and other industries, and it will be more and more favored by consumers. After adopting the in-mold labeling technology for daily chemical products, the brand image and product display effect are improved.

Compared with self-adhesive labels, it reduces the off-label phenomenon and the waste rate, saves the cost of manual labeling, and improves production efficiency. Therefore, as an important part of the outer packaging of the product, the quality detection of the finished product is an important part of the production of product packaging.

System composition

(1) Mechanical part:

The mechanical part is the core component of the system, which carries all the transmission devices and electronic hardware (industrial cameras,

Light source, industrial computer, touch screen, electrical box, etc.).

The conveyor belt adopts a vacuum adsorption belt to adsorb and fix the sample on the surface of the belt without sliding, so that the picture can be accurately taken.

(2) Hardware part:

The hardware part includes camera, lens, light source, high-speed air valve, computer, touch screen and other electrical equipment, the overall logic control of the system is realized by the high-speed FPGA chip.

Cooperation Partners

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

** Our company have served many well-known enterprises such as Coca-Cola, P&G, Unilever, ALPLA, Shriji Polymer, Berry Global, Aptar, LAMIPAK, TPAC, PACT Group, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!