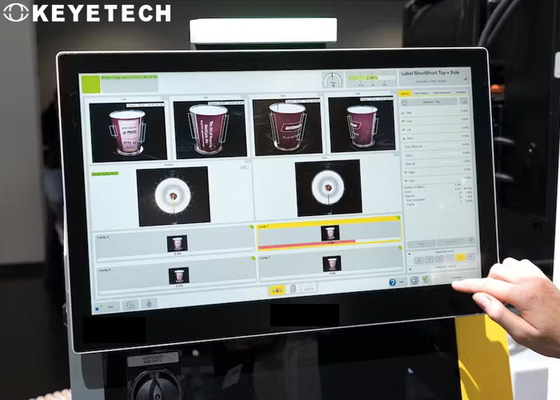

Automatic Inspection Machine Quality Control of IML Label with Vision System

Technical parameters

| 1. Product inspection status: online dynamic inspection |

| 2. Product detection speed: 130pcs/min |

| 3. Detection items: all visible surface defects on bottles |

| 4. Accuracy: 99% |

| 5. Recognition accuracy: 0.1mm |

| 6. Quality control: customized according to customer requirements |

| 7. Detection form: realize high-speed, stable and precise operation |

| 8. System performance: able to adapt to lack of light, or illumination and changes in focal length |

| 9. Detection form: It can realize the detection of different precision requirements of partitions |

Company Profile

Anhui Keye Information Technology Co., Ltd. (hereinafter referred to as Key Technology) was established in 2011. It is a national high-tech enterprise focusing on applying AI technology to the industrial field. Provide visual imaging, algorithm computing power and automatic control AI system solutions for various sub-industries.

Keye AI visual inspection overall solution adopts the world's top AI algorithm, equipped with visual analysis software and lighting, imaging and acquisition processing modules, which has the advantages of small sample size, strong generalization ability and rapid deployment. At present, the products are used in many industries such as food, alcoholic beverages, dairy products, pharmaceuticals, cosmetics, and daily chemicals.

Inspection principle

Front-end area array industrial cameras, light sources and other imaging components are directly installed on the on-site four-station production equipment. The puller motor needs to be started and stopped regularly, and moves to the next station at a constant speed. When the product is stable and orderly After being transferred to the cutting station, the high-pixel sample image captured by the area scan industrial camera is transferred to the image processing software.

Inspection Details

The solution uses 5 sets of high-resolution industrial cameras and high-performance strobe light sources to conduct all-round visual inspection for defects on the outside, inner wall, inner bottom, and outer bottom of IML cups. The inspection speed is 130 pieces/minute, and the detection of unqualified products It can be automatically removed online.

The whole set of testing equipment includes mechanical parts, visual electronic hardware and testing system software. The entrance and exit of the testing machine can be integrated with the customer's on-site conveyor line, and can be connected to upstream and downstream production equipment (such as offset printing machines, packaging machines, etc.) machines and other equipment).

Company profile

KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

** Our company have served many well-known enterprises such as Coca-Cola, P&G,Unilever,ALPLA,C'estbon, Nongfu Spring, etc., and has won praise from many users.

After-sale service

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!