Overview

Printing has the functions and effects of increasing the added value of commodities, improving product quality, and enhancing consumption.At present, the equipment level of the global printing industry is uneven, which is obviously polarized: that is, there are various high-speed, high-end, world-leading imported printing presses on the market, as well as various low-tech, low-quality printing equipment.Many small-scale enterprises use old-fashioned printing presses, and post-press production equipment is relatively backward. Some printing equipment is nearly aging, and the quality of printed products is also worrying.

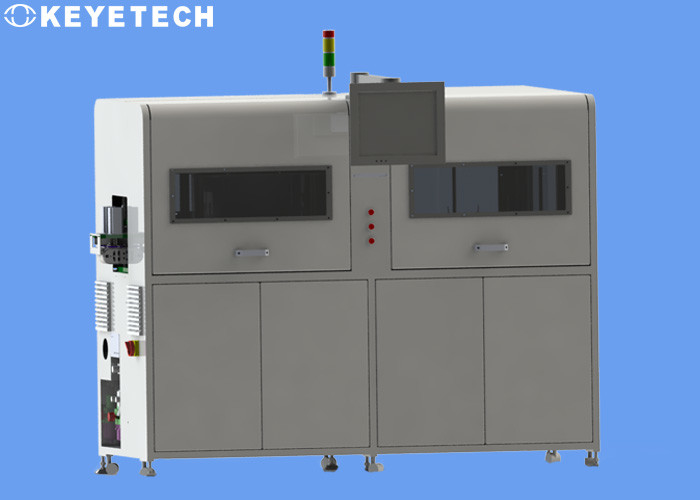

Equipment introduction

In order to improve the quality of printed products, our company has specially developed a single-station printed product defect detection machine for a certain work scene in the printing industry, this is a great significance of helping customers to eliminate product quality problems and improving product quality.

Equipment functions and features

1. The equipment uses image imaging technology to obtain various parameters and use real-time AI analysis compare standard products with sample images, and reject unqualified samples through compressed air, and automatically count qualified samples. Greatly improve production efficiency.

2. Can customized according to customer needs, using one or more cameras to detect products, and reject defective products according to standards.

3. Real-time display of sample images, running status, real-time statistics of detection results and classification information of defective products.

4. The detection function and accuracy can be flexibly changed according to on-site requirements, and 99.99% of the specified defects can be detected.

5. Save the characteristics of each sample to the model database, and you can switch the sample detection with one-click loading.

6.Statistical historical production records, multi-level authority user settings, one-key backup and restore system data.

7.The detection function is highly modular, and modules can be flexibly added or removed according to needs.

Equipment features

● It is suitable for occasions where there are few detection items or only a specific surface is detected. Generally, only one camera is needed to complete the detection task. The entire device has a simple and practical structure, which has a cost advantage compared with multi camera devices.

● It can be used in a wide range of scenarios. It can work independently, connect with related production lines, and even realize coordinated operations through combine with other related equipment.

● Strong customize, which can be customized to the customer's detection products and needs.

● Al artificial intelligence algorithm has high detection accuracy

Equipment parameters

|

Name

|

Single station textile industry quality detection machine

|

Model

|

KVIS-SC02 |

|

Software algorithm

|

Deep learning

|

Voltage

|

AC220/50HZ |

|

Voltage

|

200w |

Air pressure

|

Mpa |

|

Transfer method

|

Lossless delivery

|

Detection status

|

Online real-time detection

|

|

Detection method

|

High-speed industrial camera

|

Number of camera

|

1 |

Example of system detecting defective image:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!