Product background

With the changes in people's lifestyles and working conditions, people spend more and more time with their eyes, such as watching computers, playing mobile phones, watching TV, playing video games, etc., which are prone to visual fatigue and dry eyes. Eye drops are one of the most commonly used drug formulations for eye diseases. For many eye diseases, eye drops have a direct and quick treatment effect. Due to the small capacity of the eye drop bottle, in order to ensure the sanitation of the drop during use and prevent secondary pollution, the eye drop plug plays an important role. The quality of the eye drop plug directly relates to the drop. the quality of. Keye Technology has many years of market experience in product testing, and can customize a bottle cap testing system for enterprises, which can greatly improve testing efficiency and save productivity.

Inspection principle

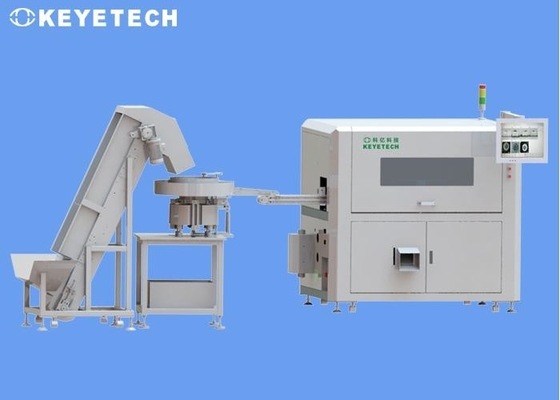

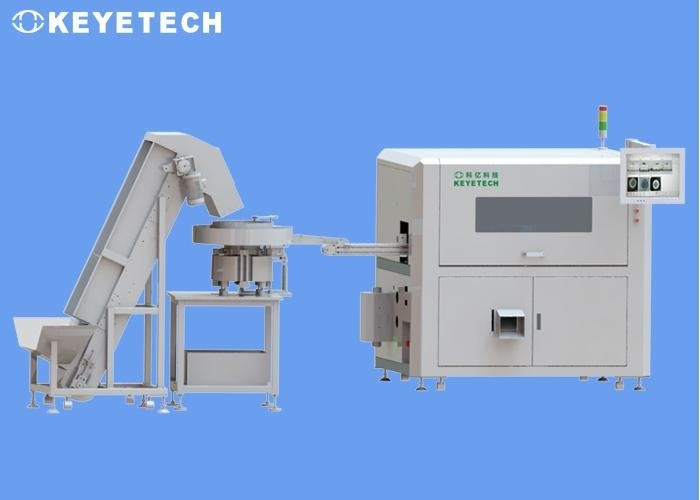

Through the material machine (vibration plate), the plug port down to the specific detection station, and then transfer the high pixel sample image to the image processing software through the industrial camera, compare with the standardized model after the good and bad products, and control the corresponding pneumatic components to eliminate the bad products, and finally collect qualified products.

The software will open the sample alignment standard, the customer on-site production personnel can control the alignment accuracy, choose the most suitable accuracy standard for their own production situation, so as to control the bad rate.

Inspection details

Our design scheme adopts 7 sets of high-pixel industrial cameras and high-performance frequency flash sources for the comprehensive defect detection of the appearance of internal plug products. The whole set of detection equipment contains the material material part, mechanical transmission part, visual electronic hardware and detection system software.The whole machine equipment can be independently arranged on the customer site, and the detection speed is 150 / minute. The equipment can operate 7 * 24 hours around the clock, and the unqualified products can be automatically eliminated online.

| System parameters |

|

Dimension

|

Reference the drawing

|

Voltage

|

220V 20A 50HZ |

|

Power

|

5-6kw |

Air

|

0.5~0.8MPa clean air without oil

|

|

Temperature

|

-20℃ ~ 60℃ |

Humidity

|

Less than 50%

|

Camera application instructions:

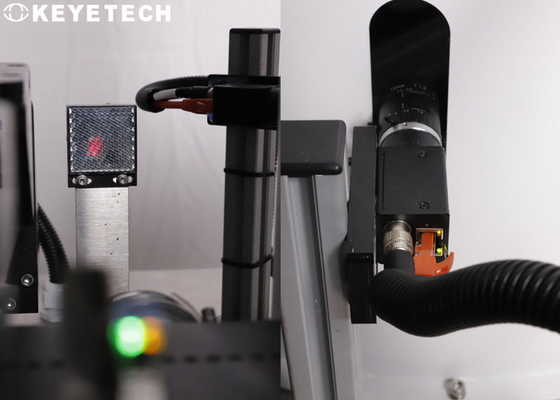

The top surface detection of the inner plug, the product is connected into the detector conveyor down through the material machine, and a set of industrial cameras is installed above the product. With the application of visual light source, the image of the top surface of the inner plug is collected for processing.

| Model |

Number of camera

|

Inspection scope

|

Inspection content and Detection precision

|

Accuracy

|

Capacity |

KVIS-

SC07 |

1 set |

Lip area

|

Black spot, stains (color different)≧0.2mm

Flash , incomplete , Blockage≧0.5mm

|

99.80% |

150

Pcs/mins

|

| 99.80% |

| 1 set |

Outside area

|

Black spot, stains (color different)≧0.2mm

|

99.80% |

| 4 sets |

Side area

|

Black spot, stains (color different)≧0.2mm

|

99.80% |

| 1 set |

Bottom area

|

Black spot, stains (color different)≧0.2mm

|

99.80% |

|

Flash , incomplete , Blockage≧0.5mm

|

99.80% |

Advantages of visual inspection

1)High detection accuracy and fast detection efficiency:CCD visual inspection equipment uses machine control according to the system, with small error and high detection rate.

2)Wide detection range to detect cosmetic defects and dimensional measurements:The multi-station inspection method can accurately measure the outline, specifications, appearance defects, product aspect ratio and other performance parameters of the product to be inspected at one time.

3)Improve product quality and error rates:Vision inspection equipment is based on system control, which can distinguish good products from bad products through automatic inspection technology, and then automatically place them in different parts.

4)Save labor costs and enable high repetitive work:CCD visual inspection can work stably for a long time, it is difficult for human eyes to observe the same object for a long time, and machine vision can perform measurement, analysis and recognition tasks for a long time. And it can continue to work, with low requirements for the natural environment of the application, in addition to saving product costs, it also greatly improves productivity.

5)Improve company competitiveness and employee safety factor:Non-contact detection, which does not cause any damage to observers and observers, improves the reliability of the system. Machine vision technology guarantees the ultimate human-machine interaction technology, which ensures a better and safer workplace.

Company profile

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!