About The Sysytem

Because of its strong oxidation resistance, diverse styles and exquisite printing, tinplate packaging containers are popular among customers and are widely used in food packaging, pharmaceutical packaging, daily necessities packaging, instrument packaging, industrial packaging, etc.

Many advantages of tinplate packaging containers, such as high strength, good formability, and strong product compatibility, have established a good reputation in the international market. Therefore, all countries generally attach importance to this kind of packaging container, which is the largest metal packaging sheet in the world. According to the different requirements of the packaging industry, the thickness of tinplate material, the amount of tin plating, and the mechanical properties have different needs.

Because the market’s feedback is good, the output is large, and the scope of application is relatively wide, manufacturers will have higher testing requirements for tinplate cover packaging, and it is necessary to use professional testing equipment to conduct all-round testing of tinplate cover. Used to bless the brand image and maintain corporate credibility.

Reference case

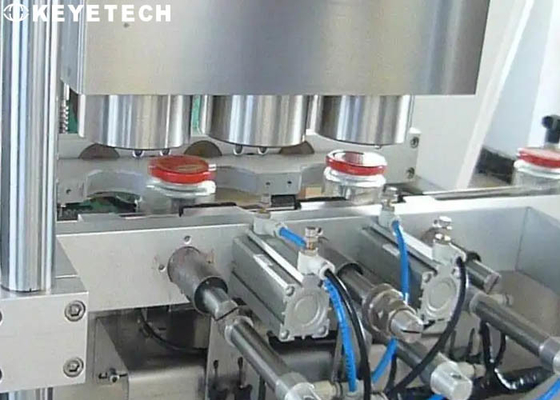

- Top surface detection of tinplate cover: detect black spots, scratches, and paint drop defects on the top surface of the cover. A camera is equipped here;

- Ø Detection inside the tinplate cover: detect whether the white collar inside the cover is protruding, black spots on the inside, foreign objects, extra white edges on the edge of the lid, and paint off the edge of the lid. A camera is equipped here;

- Ø Tinplate cover side detection: detect black spots, scratches, paint peeling, and foreign objects around the sides. Four cameras are equipped here;

- Ø The entire system is designed for the full inspection of tinplate lids. The three large modules on the top surface, inside the lid and around the sides can be individually installed or not, and customers can choose by themselves.

Summary

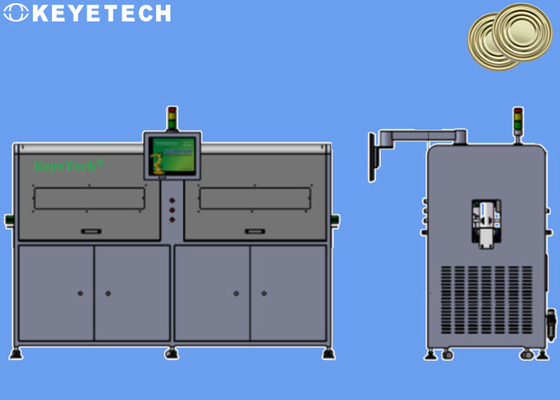

The overall equipment integrates mechanical mechanisms, visual optical hardware and detection system software, defective product rejection and counting devices. The normal detection speed is 150 pieces per minute. The entrance and exit of the detection machine can be integrated with the customer’s on-site conveyor line. The equipment can be realized. It runs 7*24 hours a day, which greatly improves production efficiency.

Tinplate cover inspection equipment, equipped with 6 sets of high-pixel industrial cameras, to comprehensively detect the appearance of tinplate cover defects. After the system collects sample images, the image processing software and standardized samples are compared and analyzed to determine good and defective products. The defective product is detected online Automatic rejection, counting function can be realized after finished product inspection, counting accuracy rate is 100%. The software will open the sample comparison standard, and the production personnel on the customer site can control the comparison accuracy and choose the accuracy standard most suitable for their own production conditions, thereby controlling the defect rate.

Inspection Details

1. The whole set of inspection equipment includes mechanical parts, visual electronic hardware and inspection system software. Both parties need to predetermine the height of the conveyor line to facilitate the on-site equipment docking.

2. According to the needs of the end customer, the number of cameras used and the corresponding content of the test are determined according to the needs of the end customer. The following table is for reference only.

3,Inspection Standard

| Model |

Number of camera

|

Inspection scope

|

Inspection content

|

Detection precision

|

Accuracy

|

| KVIS-C-SC006 |

1 set |

Top area

|

0.5mm<Black spot |

99% |

150 pcs/mins

|

| 0.5mm<Paint off |

99% |

| 4 set |

Outside area

|

0.5mm<Black spot |

99% |

| 0.5mm<Scratches |

99% |

| 1 set |

Inner area

|

0.5mm<Black spot |

99% |

|

2mm<Rubber gasket protrusion

|

99% |

|

0.5mm<Excess white edge on the edge of the lid

|

99% |

|

0.5mm<Scratches at the lip

|

99% |

4. The counting function can be realized after the finished product is tested, and the counting accuracy rate is 100%.

5. The testing equipment needs to be regularly maintained and cleaned during use (such as conveyor belt cleaning, camera cleaning, etc.). The testing equipment itself will not cause secondary pollution sources (such as debris, fine foam, etc.) to the tested samples.

6,Image capture samples

1. Mechanical part

The transmission part is the core component of the system, which carries all the transmission devices and electronic hardware (industrial cameras, light sources, industrial computers, touch screens, electrical boxes, etc.).

2. Electronic hardware

The electronic hardware part includes 6 industrial cameras, 6 industrial lenses, 3 sets of stroboscopic flash sources, 3 sets of triggers, a set of solenoid valves (reject waste), a system electrical control box (responsible for electrical and logic control), and a three-color alarm Light, a 17-inch touch screen.

After-sale service

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!