Inspection Object

Plastic white cup lid products are commonly used lids on the market. They are mostly used in various beverage shops such as milk tea, fruit drinks, coffee, etc., or in various packaged solid beverages. In a fast-paced living environment or leisurely rest time, PP cup lids can be said to be a great consumable, which continuously encourages manufacturers to accelerate production. Because of the increase in frequency of use, the quality of product packaging is the most concerned by most manufacturers. The problem is that the maximum detection height is about 23mm, and the cup diameter is about 92mm. The compatibility can be determined according to the detection requirements.

Inspection Principle

Through the conveying system, the lid which facing down are transferred to a specific station in a stable and orderly manner, and then the high-pixel sample image taken by the industrial camera is transferred to the image processing software, and the standard sample is compared and analyzed to determine whether the product is good or not. Good products, and control the corresponding pneumatic components to eliminate defective products, and finally collect qualified products.

The software will open the sample comparison standard, and the production personnel on the customer site can control the comparison accuracy and choose the accuracy standard most suitable for their own production conditions, thereby controlling the defect rate.

Inspection Details

The system equipped with 14 sets of high-pixel industrial cameras and high-performance stroboscopic light sources to conduct a full range of visual inspections for the appearance defects of cup lid products. The inspection speed is 6000-7000 per hour, and the equipment can achieve 7*24 It runs 24 hours a day, and unqualified products can be automatically rejected online.

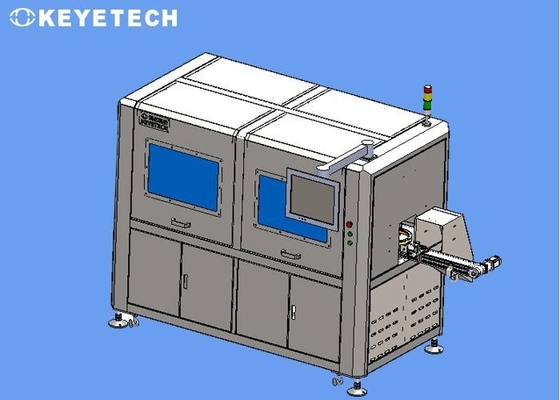

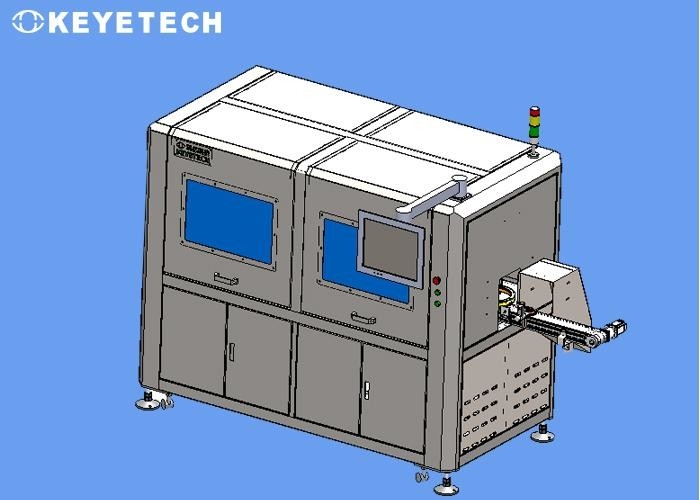

The whole system includes mechanical parts, visual electronic hardware and testing system software. The entrance and exit of the testing machine can be integrated with the on-site conveyor line (see the design drawings for details), and can be connected to the upstream and downstream according to the specific production needs of the customer. Production equipment (such as electrostatic dust removal, disinfection and other production line equipment).

| System parameters |

|

Dimension

|

Reference the drawing

|

Voltage

|

220V 20A 50HZ |

|

Power

|

5.0-6.0kw |

Air

|

0.5~0.8MPa clean air without oil

|

|

Temperature

|

-20℃ ~ 60℃ |

Humidity

|

Less than 50%

|

Reference inspection working line:

Inspection Standard

In actual testing, due to the critical fluctuation state of some testing item data, it can be adjusted through the parameter setting of the system software to achieve the actual effect.

| Model |

Number of camera

|

Inspection scope

|

Inspection content

|

Detection precision

|

Accuracy

|

Capacity |

| KVIS-SC14 |

1 set

|

Inside plane

|

Black spot, stains

|

≥0.3mm |

99.5% |

6000-7000Pcs/hour

|

| Injection incomplete |

≥0.5mm |

99.5% |

| flash |

≥0.5m |

99.5% |

|

4 sets

|

Inside edge

|

Black spot, stains

|

≥0.3mm |

99.5% |

|

4 sets

|

Outside area

|

Black spot, stains

|

≥0.3mm |

99.5% |

|

1 set

|

Top plane

|

Black spot, stains

|

≥0.3mm |

99.5% |

|

4 sets

|

Inner of the top

|

Black spot, stains

|

≥0.3mm |

99.5% |

Black spots, stains, hair, foreign objects, impurities (different colors), and burnt materials will be analyzed and processed according to the black spot detection index. The contrast difference of the gray value must be greater than 40, which can be effectively detected. If the sample has transparent oil stains or light black spots, and the gray value contrast difference is low (below 40), the detection effect cannot be achieved.

Due to the complex structure characteristics of the product, in actual inspection applications, there may be a very small detection blind zone in the junction area and structural overlap area of the planar lens imaging. The image collection cannot be within the blind zone range, so effective detection cannot be performed. At present, it is difficult to detect scratches and crushing problems on the surface of the cup lid. Because the contrast of the gray value on the visual image is smaller than the detection standard, the feature is not very obvious, so it cannot be effectively detected.

Our advantages

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!