Inspection Standard

| Model |

Number of camera |

Inspection scope |

Inspection content |

Detection precision |

Accuracy |

Capacity |

|

KVIS

-SC06

|

1 set |

Top area |

Black spot (color different) |

≥0.2mm |

99% |

Maximum 30000 pcs per hpor

|

| 4 sets |

Outside surface |

Black spot (color different) |

≥0.2mm |

99% |

| Injection incomplete |

≥0.5mm |

99% |

| Flash |

≥0.5mm |

99% |

| 1 set |

Concave surface |

Black spot (color different) |

≥0.2mm |

99% |

| Transformation |

≥1.0mm |

99% |

| Flash |

≥0.5mm |

99% |

Inspection Object

The Glycerine Enema cap product, divided into two size structures, the medical supplies industry, the specific product sizes are as follows (see actual samples for details):

CAP A, the height is 14.6mm, the maximum diameter of the cover is 9.9mm

CAP B, the height is 15.0mm, the maximum diameter of the cover is 9.0mm

To achieve the compatibility test of the above two products, it needs to involve the adjustment of the material handling mechanism and the guide rail, the position adjustment of the inspection machine interface, the camera focus adjustment, and the switching application of the detection software. In actual use, the customer's on-site personnel need to be proficient in operation.

Summary

The whole system is a visual inspection machine for the lip caps, which integrates cap management equipment, conveying mechanism, visual system hardware and inspection software, and defective product rejection device. The maximum inspection speed is about 30,000 pieces/hour, and the equipment can achieve 7*24 hours. Operation, greatly improving production efficiency.

The inspection equipment is equipped with a total of 6 sets of high-pixel industrial cameras to comprehensively detect the appearance of defects of the product. After the system collects sample images, the image processing software is compared with standardized samples to determine good and defective products, and the defective products are automatically eliminated online. , The software will open the sample comparison standard, and the production personnel on the customer site can control the comparison accuracy and choose the accuracy standard most suitable for their own production conditions, thereby controlling the defect rate.

| System parameters |

|

Dimension

|

Reference the drawing

|

Voltage

|

220V 20A 50HZ |

|

Power

|

2.5-3.0kw |

Air

|

0.5~0.8MPa

clean air without oil

|

|

Temperature

|

-20℃ ~ 60℃ |

Humidity

|

Less than 50%

|

In actual testing, due to the critical fluctuation state of certain testing item data affecting the judgment, it will cause a certain probability of product misdetection, which can be adjusted through the parameter setting of the system software to achieve the actual effect.

Defect characteristics (different colors) such as black spots, stains, hair, impurities, etc., will be analyzed and processed according to the black spot detection index. The difference in gray value contrast must be greater than 40 (it can be understood as: place the sample at a distance of one arm) , About 30cm or more, the black point feature can be seen visually), which can be effectively detected. If the sample has transparent oil stains or light black spots, and the gray value contrast difference is low (below 40), the detection effect cannot be achieved.

Due to the complex structural features of the system, in actual inspection applications, there will be a certain blind area in the overlapping area of the structure of the planar lens imaging, and the image collection cannot be within the range of the blind area, so effective inspection cannot be performed.

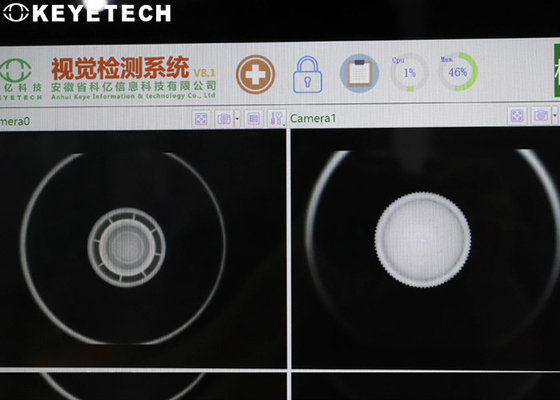

Working principle of the cameras

- Concave surface detection. The product is delivered to the inspection station in a stable and orderly manner with the lid facing upward through the docking capping machine. A set of industrial cameras is installed on the top of the product and used with the visual light source to collect the concave image of the product for analysis and processing. .

-

- Outside detection, taking into account the structural characteristics of the product, 4 sets of cameras are required to form the outer side of the ring to detect, cooperate with the use of visual light sources, and the imaging does not interfere with each other. System analysis and processing are

-

- Top surface detection, the product enters the glass turntable mechanism at the back of the equipment, opens the view angle of the top surface of the product, and installs a set of industrial cameras under the system to cooperate with the visual light source to collect the top surface image of the product for analysis and processing.

-

- After the finished product is tested, the counting and binning function can be realized. The testing equipment needs to be maintained and cleaned regularly during use (such as conveyor belt and glass plate cleaning, camera cleaning, etc.).

Image capture samples

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!