Many countries in the world are large agricultural countries. In the process of crop growth, spraying pesticides is an indispensable main way to eliminate insects and weeds. Therefore, the packaging of pesticides has a very important impact on the industry. Pesticides are relatively corrosive. At the same time, in order to ensure the validity period of the pesticides, the air-tightness and safety of the packaging are very important. Many countries and regions have very strict requirements on the packaging of pesticides, which also affects the manufacturers' high standards and requirements for production. However, traditional manual inspections cannot meet the precise inspection of drug caps. Therefore, professional visual inspection technology is introduced to replace human eyes. Accurate inspection of product specifications and models. Keyi Technology has many years of industry experience and can use industry big data information to match the data of test samples in real time to check possible problems in the production line

Inspection Object:

Bottle cap products are used in the pesticide packaging industry. See actual samples for details.

Note: If the product diameter difference is within 1/3, and the height difference is within 1/2, the system software can be switched with one key to realize compatibility detection.

Inspection Principle:

Through the docking shim machine conveyor line, the products are stably and orderly (the products must be conveyed in a straight line, and there is a distance between the products not less than the product radius.) to a specific station, and then through an industrial camera The captured high-resolution sample images are transmitted to the image processing software, and the good and defective products are determined after comparison and analysis with the standardized samples, and the corresponding pneumatic components are controlled to reject the defective products, and finally the qualified products are output online.

The software will open the sample comparison standard, and the production personnel on the customer site can control the comparison accuracy and choose the accuracy standard most suitable for their own production conditions, thereby controlling the defect rate.

Inspection Details

Our design plan adopts a set of high-pixel industrial camera and high-performance stroboscopic light source to visually inspect the concave surface of the bottle cap. The inspection speed can be matched with the line speed not less than 10,000 per hour. The equipment can achieve 7*24 hours. Run, unqualified products can be automatically rejected online.

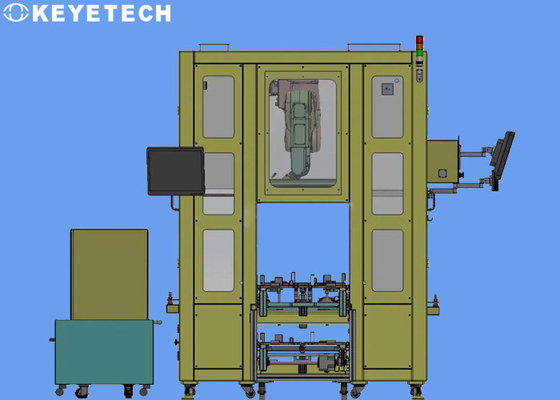

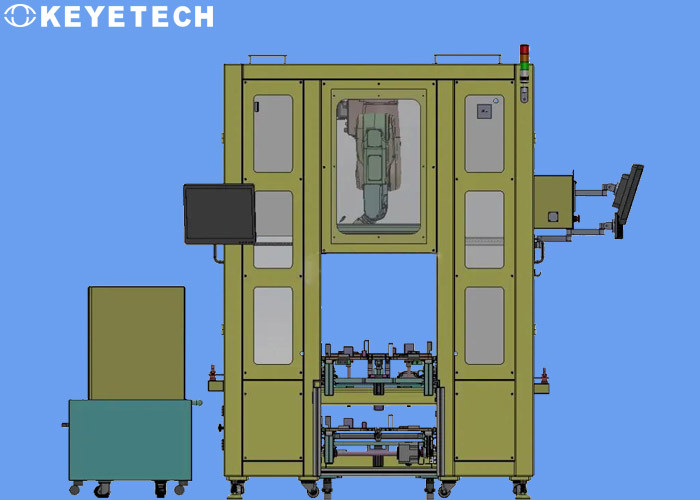

The whole set of inspection equipment includes mechanical parts, visual electronic hardware and inspection system software, which can be connected to the customer's on-site conveyor line, which occupies a small space and is relatively easy to operate.

| System parameters |

|

Dimension

|

Reference the drawing

|

Voltage

|

220V 20A 50HZ |

|

Power

|

1.0-2.0kw |

Air

|

0.5~0.8MPa

clean air without oil

|

|

Temperature

|

-20℃ ~ 60℃ |

Humidity

|

Less than 50%

|

Inspection Standard

In actual testing, due to the critical fluctuation state of certain testing item data affecting the judgment, it will cause a certain probability of product misdetection. The parameter setting of the system software can be adjusted to achieve the actual effect.

| Model |

Number of camera

|

Inspection scope

|

Inspection content

|

Detection precision

|

Accuracy

|

Capacity |

| KVIS-SC01 |

1 set

|

Concave surface

|

Injection incomplete

|

≥0.5mm |

99% |

10000

Pcs/hour

|

|

Transformation

|

≥1.0mm |

99% |

|

Missing thread

|

- |

100% |

- Ø Black spots, stains, hair, and impurities (different colors) will be analyzed and processed according to the black spot detection index. The contrast difference between the gray values of this item must be greater than 40, which can be effectively detected. If the sample has transparent oil stains or light black spots, and the gray value contrast difference value is low (below 40), the detection effect cannot be achieved.

- Due to the complex structural features of the product, in actual inspection applications, there will be a certain blind area in the overlapping area of the structure of the planar lens imaging, and the image collection cannot be effectively detected.

After the finished product is tested, the counting function can be realized, and the counting accuracy rate is 100%.

The testing equipment needs to be maintained and cleaned regularly during use (such as camera lens cleaning, etc.).

5, Image collection (for reference only)

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!