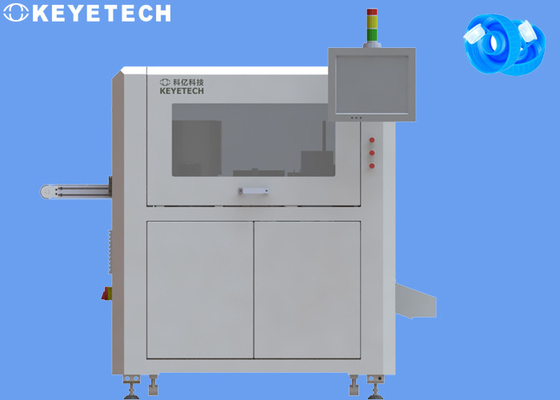

Industrial Online Aoi Equipment Inspection System for 5 Gallon Bucket Cap

Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

Inspection Details

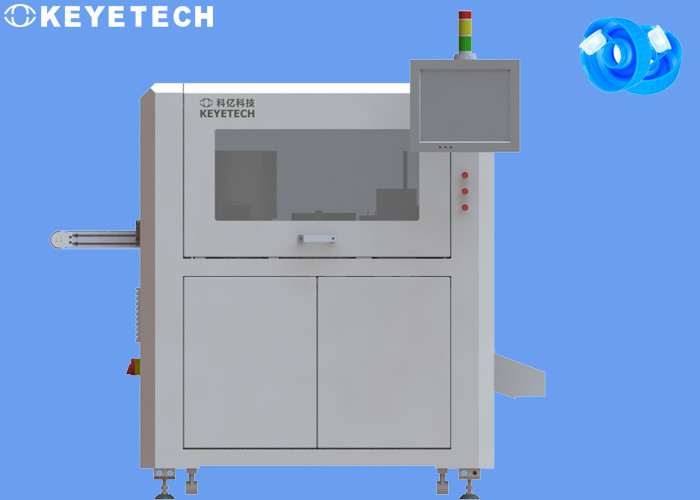

The whole system integrates mechanical mechanisms, visual optical hardware and detection system software, defective product rejection and counting devices. The normal detection speed is 200 pieces per minute. The entrance and exit of the detection machine can be integrated with the customer’s on-site conveyor line. The equipment can be realized.

It runs 7*24 hours a day, which greatly improves production efficiency.

This inspection equipment is equipped with 6~10 sets of high-pixel industrial cameras to comprehensively inspect the appearance defects on the side of the cover, the inside of the cover and the bottom of the cover. After the system collects the sample image, the image processing software is compared and analyzed with the standardized sample to determine the good product.

Note:

1. Detection of the outer side of the cap. Taking into account the special structure of the cover, the material sorting method of this plan is a turntable type. The plan designs a set of optical integrating cavity modules and 4 sets of industrial cameras are used, and the imaging does not interfere with each other.

2. Detect the outer bottom surface of the cover. The outer bottom of the cover is suspended through a clamping mechanism, and a set of industrial cameras are installed below, which can be used in conjunction with the visual light source to collect images of the outer bottom for processing.

3. Inspect the inside of the lid. 5 sets of industrial cameras are installed on the top of the lid and used with two sets of visual light sources to collect the images of the bottom of the inner side wall of the lid and the inner bottom of the lid for processing.

Camera Layout

| Model |

Number of camera

|

Inspection scope

|

Inspection content

|

Detection precision

|

Accuracy

|

Capacity |

| KVIS-SC10 |

4 sets

|

Outside area

|

Black spot , stains(color difference )

|

>0.2mm |

99.98% |

300

Pcs/mins

|

|

Opening ring missing

|

|

100% |

|

Roughly , flash

|

>0.2mm |

99.98% |

|

1 set

|

Inner bottom

|

Black spot , stains(color difference )

|

>0.2mm |

99.98% |

|

Foreign material

|

>0.2mm |

99.98% |

|

4 sets

|

Sealing ring

|

Incomplete

|

≥1mm |

99.98% |

|

1 Set

|

Top area

|

Black spot , stains(color difference )

|

>0.2mm |

99.98% |

|

Film incomplete

|

>2mm |

99.98% |

|

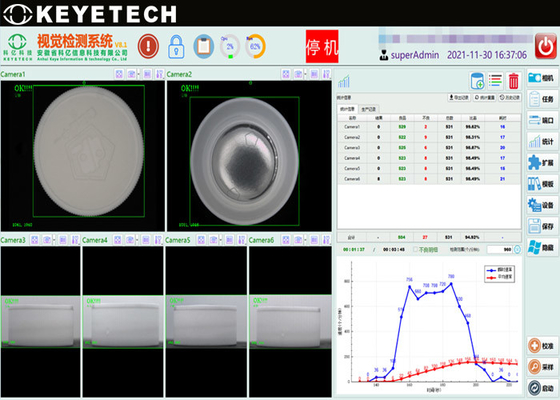

Software Function

- Enabling and disabling the system detection function

- Adjustment of detection index parameters and accuracy

- Template sampling and storage, sample detection information storage and recall

- Camera screen calibration function

- System real-time production information (qualified rate, total output, speed, etc.) display, historical production information browsing, export and storage functions

- Permission management based on login account (For example, the general operation user disables the parameter adjustment authority).

- SOperation and adjustment of the mechanical part of the system (If the transmission device is turned on, the alarm signal is adjusted).

After-sale Service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!