Inspection standards

| Model |

Camera number |

Detection |

Inspect |

Accuracy |

Precision |

Speed |

|

KVIS-

SC14

|

1set |

Bottle mouth plane |

Black spots, stains |

≥0.2mm |

99% |

3600pcs/h |

| Poor incision |

≥0.5mm |

99% |

| Deformed |

≥0.5mm |

99% |

| 6set |

The outer side of the bottle |

Black spots, stains |

≥0.2mm |

99% |

| 6set |

Outside side of bottle

|

Black spots, stains |

≥0.2mm |

99% |

| Label offset |

≥1.0mm |

99% |

| 1set |

Outer bottom of the bottle |

Black spots, stains |

≥0.2mm |

99% |

| Through hole |

≥0.5mm |

99% |

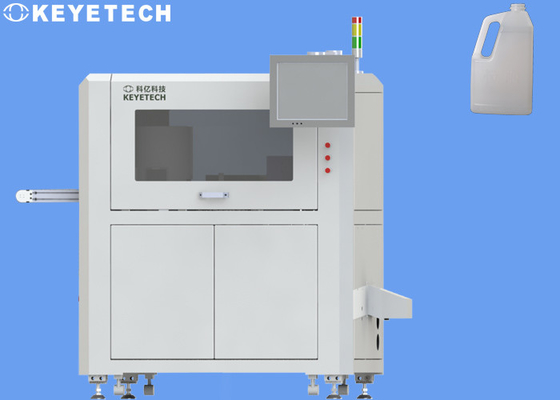

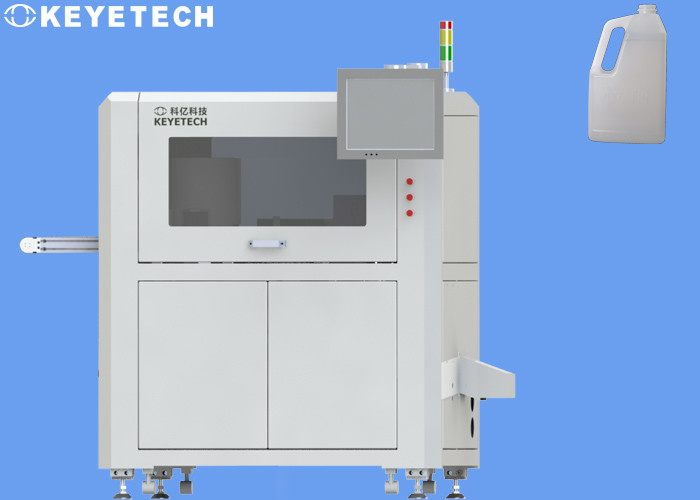

Detecting products

Condiment packaging bottles, HDPE material, with a handle structure, the bottle body has a single-sided label when detecting, see the actual sample for details.

Detection principle

Stably and orderly transfer the barrel and bottle products to a specific station according to a fixed orientation (such as the handle structure area forward), and then transmits the captured sample image to the image processing software through the high-pixel industrial camera, compares with the standardized sample and distinguishes the defective product and the good product, and controls the corresponding pneumatic components to reject defective products and finally collect qualified products.

The software sets the comparison standard for the samples, operators can control the comparison precision and choose the precision standard that best suits themselves, thereby controlling the defect rate.

Detection details

Our design plan uses 14 sets of high-pixel industrial cameras and high-performance stroboscopic light sources, and conducts a comprehensive detection of the bottle mouth, bottle bottom and bottle body defects of the product. The whole set of detection equipment includes mechanical parts, visual electronic hardware and detection systems. The software, the entrance and exit of the detector can be integrated with the conveyor line. The detection speed is 3600 pieces per hour. The equipment can realize 7*24 hours of operation, and the unqualified products can be automatically rejected online.

| System operating parameters |

| Dimensions |

See the design drawings

for details

|

Power and frequency |

220V 20A |

| Total power |

5.0~6.0 kw |

Air pressure |

0.5~0.8MPa Purify and oil-free |

| Working temperature |

-20℃ ~ 60℃ |

Working humidity |

Below 50% relative humidity |

Instructions for camera use:

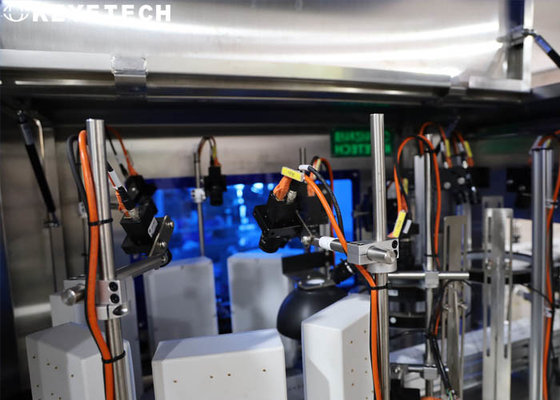

Bottle mouth plane detection, add 1 set of industrial cameras above the bottle body to use with visual light source to collect the image of the bottle mouth area for processing.

-Detection of the side surface of the bottle body. Considering the special structure of the bottle body and the height of the bottle body beyond the single-camera viewing angle range, the plan is designed to install cameras on the upper and lower parts, and each part uses 6 sets of cameras to form a toroidal detection, A total of 12 sets of industrial cameras, with the use of visual light sources, imaging does not interfere with each other, and the system is carried out after image acquisition.

Detect the outer bottom surface of the bottle. The bottom of the bottle body is suspended through a clamping mechanism, and 1 set of industrial cameras is installed below, which is used in conjunction with a visual light source to collect images of the outer bottom for processing.

The detection equipment needs to be maintained and cleaned regularly during use (such as conveyor belt cleaning, camera cleaning, etc.), and the counting function can be realized after the finished product is tested.

System composition

This plan is explained from the following aspects: mechanical part, hardware part, and software part. The specific instructions are as follows:

(1) Mechanical part:

The mechanical transmission part is the core component of the system, which carries all the transmission devices and electronic hardware (industrial cameras, light sources, industrial computers, touch screens, electrical boxes, etc.). The conveyor belt adopts negative pressure adsorption technology to ensure that the electronic system takes images quickly and accurately.

(2) Hardware part:

The hardware part includes cameras, lenses, light sources, pneumatic devices, computers, touch screens and other electrical devices.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!