Toothpaste is an inconspicuous product in daily life, few people notice the packaging of toothpaste in daily life. However, in actual production, the convenience of toothpaste tube shoulder design is closely related to the quality of toothpaste. The connection between the shoulder part of the toothpaste tube and the body of the toothpaste tube is unreasonable, or there is any defect in the production of the toothpaste tube shoulder, which leads to the poor sealing of the toothpaste, the chemical substances in the paste are easily oxidized and deteriorated, and the bacteria are easy to adhere. Bring bacteria into the mouth cavity while cleaning the teeth. A good toothpaste cover not only has a good seal ability, but also is not easy to cause unnecessary waste. therefore. The whole part of toothpaste packaging must undergo professional packaging detection after production.

Keye Techhas practiced and designed a complete set of detection systems for toothpaste packaging for the detection of toothpaste packaging. Taking the shoulder of the toothpaste tube as an example, I will explain the general content of the plan for everyone:

1. Equipment overview

Since the tube shoulder is a colorless and transparent part, the detection function needs to be divided into two parts: the side optical detection part and the front optical detection part.

When working, the tube shoulder pieces enter the silo first, and enter the centrifugal turntable through the lifting of the hoist. Then use the centrifugal principle to transport the tube shoulder to the conveyor belt and enter the side optical detection system part. The detection part uses four high-speed industrial cameras to take 360-degree photos of the side of the product to detect defects such as lack of material, oil stains, black spots, and overlap on the side of the product, and to eliminate defective products; The mouth and bottom are detected, mainly detecting defects such as product overlap and lack of material; the equipment has the characteristics of compact space, convenient installation and deployment, accurate and fast detection, simple operation and easy-to-use.

2. Equipment function

Detection function

| Detection Indicator |

Lack of glue at the tube shoulder, overlap, oil stains, and closed tube openings |

| Detection speed |

200 pcs/min |

| Detection range |

360 degrees on the side of the tube shoulder, the threaded mouth, and the bottom in contact with the hose |

| Detection accuracy |

Lack of glue≥1mm,overlap≥0.6mm,Oily area≥0.5mm² Automatic rejection |

| Detection precision |

99.8%,Mistake rate≤0.1%,Nozzle closed100% |

System functions

-Enable and close the system detection function

--Adjustment of detection index parameters and accuracy.

Template sampling and storage, sample detection information storage and recall.

-Camera screen calibration function

-System real-time production information (qualified rate, total output, speed, etc.) display, historical production information browsing, export and storage functions.

-Permission management based on the login account (such as general operation users disable parameter adjustment permissions)

-Operation and adjustment of the mechanical part of the system (such as: air valve jet time adjustment, camera trigger time adjustment)

-Protection function: Add protective cover to moving parts such as motor shaft.

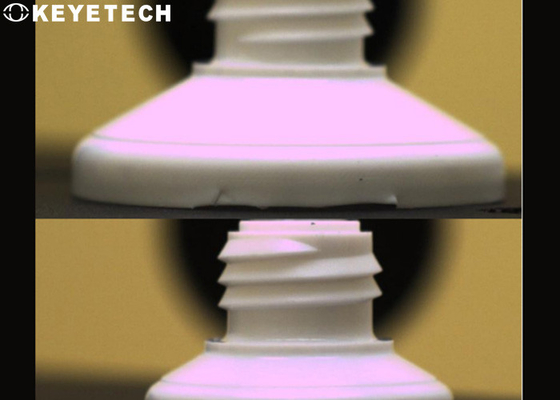

Sample detection pattern part example

The following patterns show some examples of defective sample patterns, including but not limited to the defects shown in the following images:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!