Company Profile

Keye Technology relies on the Keye Laboratory of Pattern Recognition of the University of Science and Technology of China, and has a high-level doctoral R&D team covering the entire technology chain of optics, mechanics, electricity, computing and software.

Through the project practice in the fields of packaging containers, 3C, medicine, textile, food, etc., the KVS-AI software and hardware platform has been created, so that AI technology can be transformed into real productivity. We provide visual imaging, algorithm computing power and automatic control AI system solutions for various sub-industries.

Core Technology

1. Automatic binarization: Use deep neural network to segment the foreground and background of the image. Compared with the traditional binarization method, it can be applied to a variety of lighting conditions, and the edge segmentation is smoother, fast and robust The advantage of high sex.

2. Adhesive egmentation algorithm: The method based on connected domains cannot segment the adhered. The deep neural network is used to segment the adhered at an instance level, which can reach a speed of 1000fps and can process the adhered in real time.

3. Attribute recognition algorithm: adopts lightweight neural network and integrates semi-supervised learning method. Iterative optimization of the model can be carried out with only a small amount of data marked by the user. It has the advantages of high accuracy, fast speed, and convenient deployment.

| Model.No |

KVS |

Accuracy |

99.8% |

| Task training |

Cloud platform |

Inspection |

on-line / off-line |

| Voltage |

220V±10%,50Hz |

Current |

5kw-7kw |

| Ambient temperature |

10~30℃ |

Environment humidity |

Relative temperature≤85% |

System Applications

- Filling beverage detection (bottle body, cap closures, liquid level, impurities, labels)

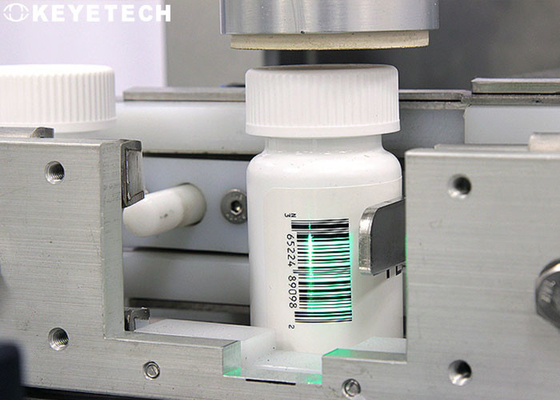

- Code detection (missing, fuzzy, uncoded)

-

** Our company have served many well-known enterprises such as Coca-Cola, P&G,Unilever,ALPLA,C'estbon, Nongfu Spring, etc., and has won praise from many users.

After-sale Service:

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!