Products background

Gears and their gear products are important basic parts of mechanical equipment, and play a very important role in the overall power system. The main transmission components of most complete sets of mechanical equipment are gear transmission. The quality of gears directly affects the service life of the machine and safe production. Therefore, the automatic detection technology of gear appearance that can improve the quality of gear shipments is also of great significance to the machinery industry.

The gear design is a very important part of the gear processing manufacturer, and the design is not in place to determine the performance of the gear. At this stage of design, gear manufacturers must choose efficient and reliable gears with appropriate casting materials and reasonable structural design. In the production process of gear products, there may be appearance defects such as broken teeth, short teeth, broken teeth, missing teeth, crooked teeth, and sharp edges, which will affect the accuracy of the gears and cause problems with occlusion. In the quality inspection process, these defective products must be eliminated.

Inspection principle

Generally, companies rely on human eye inspection, or inspectors identify gear defects one by one under a microscope. The inspection efficiency and accuracy are low, and the standards of inspectors cannot be completely unified, so the accuracy is difficult to guarantee. In addition, when the gears are mass-produced, manual inspection alone cannot cope. Applying machine vision inspection equipment to detect gear appearance defects can avoid and solve these problems.

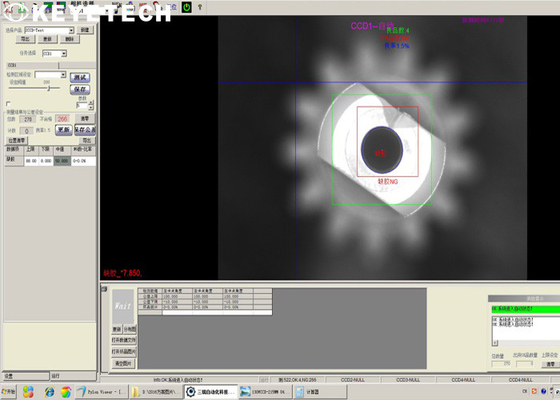

Gear appearance inspection equipment relies on machine vision and uses machines instead of human eyes for measurement and judgment. The equipment automatically collects the image of the inspection object, and the image software system will process and analyze the collected images in real time according to the process standards proposed by the customer, determine whether the gear product is qualified, if not, what defects exist, and output the processing results.

Equipment detais &configurations

| Name |

Gear Inspection machine |

Size |

900*800*1850mm |

| Computer |

Industrial PC |

Monitor |

19 inch |

| Industrial camera |

2 set |

Industrial lens |

2 set |

| Glass turntable |

1 pcs |

Samples |

0.6-30mm(diameter) |

| Feeding equipment |

vibration plate, direct vibration, controller |

Speed |

200-400/min |

Through industrial cameras, industrial lenses, vision controllers, light sources, customized industrial computers, vision software, etc., a visual inspection system is used to obtain image acquisition, identify and judge defects. Within the field of view of the camera, the deviation of the incoming product position is required to be small.

System advantages

1. High detection accuracy. Machine vision inspection equipment uses high-resolution industrial cameras, lenses and light sources to obtain product appearance images, and combines with visual image processing software to comprehensively inspect precision components.

2. High detection efficiency. The machine has a fast detection speed and can work 24 hours a day to continuously and stably output accurate detection results. However, the time that people can continue to work effectively is limited, and they are prone to fatigue and lack of energy during the repeated mechanized detection process, resulting in poor detection results.

3. Digital statistics management. Machine vision inspection equipment can perform statistics and analysis on inspection data, establish a database of defective products, facilitate subsequent research and analysis, effectively improve production methods, and control product quality.

4. The overall cost is lower. Manual inspection is a long-term, ongoing cost input, and today both labor and administrative costs are rising. The investment of visual inspection equipment is mainly in the early stage, and the one-time investment ensures long-term output.

Machine vision inspection occupies an increasingly important position in the field of industrial inspection due to its high inspection accuracy and speed, as well as the advantages of effectively avoiding subjectivity and individual differences brought about by manual inspection.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!